Description

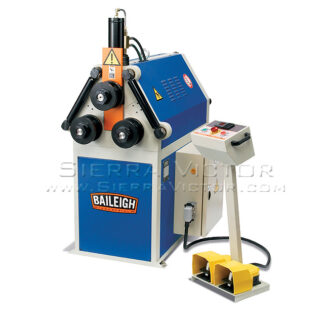

- Our machines are strong and reliable with their St-52 weld construction body. Minimum flexion causes less deformation, by the help of our machines’ enlarged roll diameters. By the help of big measurements of bearings, durability and high bending momentum can be obtained. Hydraulic cylinders’ power enables to bend the bigger parts without any difficulty. Practical and universal rollers create the possibility of easiness about bending various kinds of profiles, and this feature gives the opportunity of being more powerful and firm.

- Our Profile Bending Machines are 3 Rolls driven. This feature allows having the possibility of making, the high capaticied bending processes, real. Secondly, our 3 Rolls Driven machine minimizes the slip of the materials during the bending process.

- Hydraulic Guide Rolls can move towards three directions, to reduce the deformations and to facilitate bending processes, especially about angles and spirals.

- There are private productions up to the customers’ demands on Big Profile Bending Machines, in addition to standard production. For instance;

- The distance between the rolls can be lengthened to increase the bending capability.

- Three rolls can be produced as driven by separate gearboxes and hydraulic motors. (Except APK 360 & 550 on which this system exists)

- The movement of lower rolls and the rotation movement can be done in the same time with some hydraulic arrangements.

- The lower rolls’, rotation’s and hydraulic guide rolls’ movements can be arranged according to each other.

- Placement of the hydraulic tank up to the customer’s demand.

- Assembling the control panel on the machine body.

- Lower rolls’ movements can be adjusted too slowly for sensitive bending.

- The bending speed can be increased.

FOR MORE INFORMATION SEE PRODUCT FEATURES TAB

EQUIPPED WITH:

- Machine body is steel (ST-52) construction

- On APK81 rolls are driven by a hydraulic motor+planetry gearbox and gears

- Shafts made of special steel, hardened and grounded

- One set standard rolls

- Lower rolls hydraulic moveable up and down

- Digital display for lower rolls

- Separate and moveable control panel

- Hydraulic guide rolls are moving in two directions

- Manual lubrication

- Horizontal & vertical working

- Suitable for CE

OPTIONAL MODELS:

APK 81-DRO, Capacity: L3″ x 3″ x 5/16″ (In Stock w/Free Shipping) – $37,995.00

APK 81-NC, Capacity: L3″ x 3″ x 5/16″ – $50,000.00

APK 81-CNC, Capacity: L3″ x 3″ x 5/16″ – $52,000.00

SPECIFICATIONS:

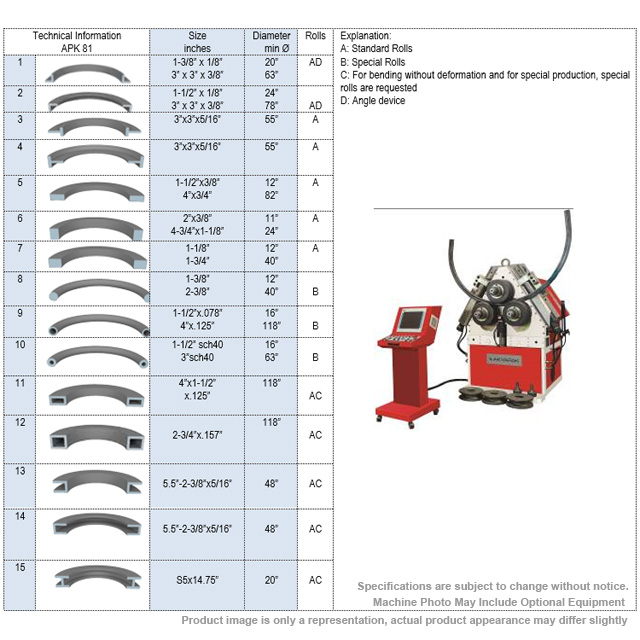

Capacities: L3″ x 3″ x 5/16″

Max. section modulus: 1.0 in3

Roll Diameter Ø: 9.65″

Shaft Ø: 3.15″

Bending Speed: 14″ per/min

Motor Power (HP): 7.5 & 1

Length x Width x Height: 54″ x 41″ x 61″

Weight: 3,750 lbs.

*The dimensions can be changed according to the position of hydraulic tank.

*Data based upon steel 36,000 PSI yield point.

*Pictures shown in this offer are just for demonstration, might be with or without optional equipment

Specifications are subject to change without notice.

NOTE: Data is provided by the manufacturer.

WARRANTY: 1 YEAR

OPTIONAL ITEMS: CALL FOR PRICE

Special Guide Rolls for Angle Materials

Two Speeds

Variable speed of rotation

Hydraulic Guide Rolls

Digital Readout for Guide Rolls

NC Control System (AK 300CS3)

CNC Control System (AK 400CS3)

Digital Display for Hydraulic Guide Rolls: Digital displays show the positioning of hydraulic guide rolls which makes bending process easier for the operators. The maximum positions of hydraulic guide rolls can be limited from those control panels. So that hydraulic guide rolls do not go up to the maximum available positions.

Hydraulic Pulling System: While bending H-I-U profiles in hard-way, there occur a big force on weaker side of these profiles which results in enormous deformation. In order to prevent this deformation, hydraulic pulling system is developed by AKYAPAK. This system consists of hydraulic pulling arm, arm guide for channels, arm guide beams and special rolls suitable for bending H-I-U profiles.

Arm Guide: This equipment is mounted on the hydraulic pulling arm. Same arm guide can be used for H and I profiles. But it is necessary to use different arm guide for U profiles.

Arm Guide Rolls These equipments are mounted on the arm guide. These rolls are different according to each type and size of the profiles.

*CONTACT US FOR COMPLETE LIST OF OPTIONAL EQUIPMENT