Description

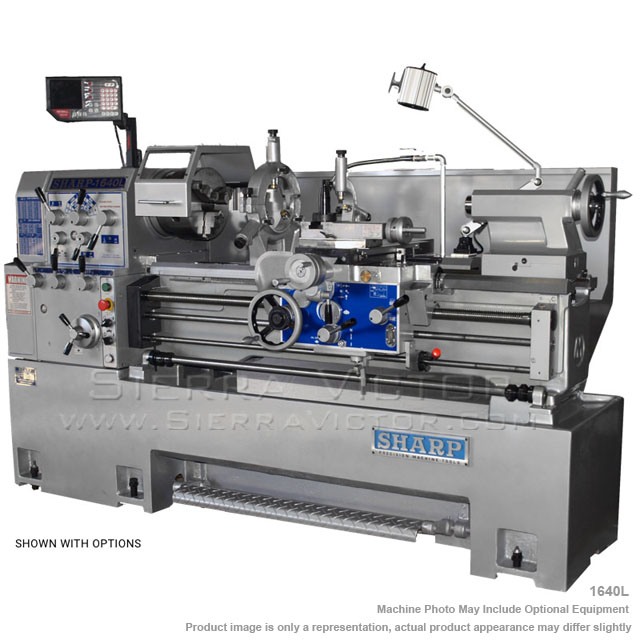

SHARP 16″ – 18″ x 40″ – 80″ L-Series High Speed Precision Lathes

- This model is designed with 3.18” spindle hole which is unique for 16” and 18” swing lathes. Due to its one piece casting machine base, it can support heavier cutting on large diameter materials. The large through hole allows most 3” diameter oil pipes to be machined.

- Models: 1640L 1660L 1860L 1880L

- 16″ x 40″, geared head, D1-8 camlock, 3.18″ bore, 7.5 HP, 20-2,000 rpm (12)

- 16″ x 60″, geared head, D1-8 camlock, 3.18″ bore, 7.5 HP, 20-2,000 rpm (12)

- 18″ x 60″, geared head, D1-8 camlock, 3.18″ bore, 7.5 HP, 20-2,000 rpm (12)

- 18″ x 80″, geared head, D1-8 camlock, 3.18″ bore, 7.5 HP, 20-2,000 rpm (12)

- Direct selection for inch/metric threads

- One piece Meehanite casting bed

- 12-speed geared head (40-2,000 rpm)

- 3.18” spindle bore, largest spindle in this size lathes. More choices for different diameter of materials to be machined.

- All headstock gears are hardened and ground made from Chrome-Moly material gives long lasting power and accuracy in machining.

- High precision pair of matched angular contact bearings supporting the front end of head stock, and rolling bearing for the rear end support. This arrangement allows high accuracy of the spindle even under heavy cutting conditions.

- Wide range of feeds and threads. Selection done by “pull and lock” handles to avoid slipping in engagement of gears.

Jog button is equipped at headstock for easy engagement of gears before cutting. - Jog button is equipped at headstock for easy engagement of gears before cutting.

- One piece casting bed instead of sheet metal connected legs ensure dampening of vibration and permanent straightness of the bed ways.

- The carriage and cross slide ways are lubricated by push button knobs.

- The removable gap increases the swing by an extra 8” to accommodate larger work pieces that are short in length

- 5 position carriage stop for pre-positioning of carriage feed distance.

- “Tang” in tail stock for easy “knock out” of centers stuck in tailstock

STANDARD EQUIPMENT:

- 3-jaw 10″ chuck, 12” Face plate, steady rest

- Removeable gap, back plate

- Coolant system, American tool post

- Full length splash guard

- Center sleeves, dead center, tool kit

- Wired 220V or 440V

ITEM: 16″ – 18″ x 40″ – 80″ High Speed Precision Lathes

MANUFACTURER: SHARP

MODEL: L-SERIES

PART: 1640L / 1660L / 1860L / 1880L

Item/Model: SHARP L-SERIES: ENTER MODEL#