Description

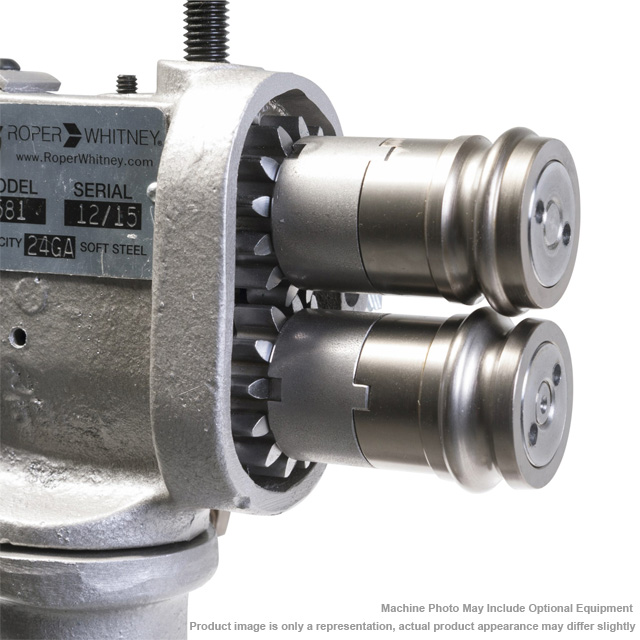

ROPER WHITNEY 24 gauge Crimping & Beading Machine NO. 0581

- Pexto forming machines offer a broad variety of shapes and capabilities in forming sheet metal for a combination of uses: beading, crimping, setting down, double seaming, turning, burring, wiring, elbow edging, flanging, and flattening. All are precise in the job they do and are readily adaptable to job requirements. The roll chart is indicative of their flexibility. Most are portable and may be set up at the job with a clamp-on base. These machines include ogee bead and crimping rolls to provide one pass combined crimping and beading. They are adjustable for deep or shallow beading and for “fade-away” crimping. By replacing the beading rolls with spacing collars (furnished), the machine can be used for crimping only. The No. 0581 has a maximum capacity of 24 gauge. In stock and ready to ship.

- MADE IN USA

STANDARD EQUIPMENT:

- PART#350000015: Crimping Roll – Upper

- PART#350000016: Crimping Roll – Lower

- PART#350000017: Ogee Bead Roll – Upper

- PART#350000018: Ogee Bead Roll – Lower

SPECIFICATIONS:

Catalog No. 164005810

Maximum Capacity – Mild Steel: 24 ga

Ratio Gearing: 1:1

Weight ( Approximate ): 30 lbs

OPTIONAL ITEMS:

350000153: Ogee Bead Extended Roll-Upper

350000154: Ogee Bead Extended Roll-Lower

381700082: Spacing Collar ( 2 required – Sold individually)

259700013: Standard Gauge

Specifications are subject to change without notice.

NOTE: Data is provided by the manufacturer.

WARRANTY: 3 YEAR – Limited

Note: Consumable tooling is not covered under the 3 year manufacturer’s warranty.