Description

The BETENBENDER 10ft x 50 Ton Hydraulic Press Brake Model 10-50 is a powerful and versatile press brake that is for businesses that need to produce high-quality parts in a variety of shapes and sizes.

- ** FREE SHIPPING TO COMMERCIAL ADDRESS THAT CAN OFFLOAD** SHIPPING IS TO LOWER 48 STATES ONLY. OTHER AREAS PLEASE EMAIL FOR FREIGHT QUOTES.

- Due to unprecedented rise in steel costs, the manufacturer is requiring ALL distributors to add a 17% steel surcharge to the base price of Betenbender Machines. Price shown is the base price.

Here are some additional advantages of the BETENBENDER 10 ft x 50 Ton Hydraulic Press Brake Model 10-50:

- Long bed length: The long bed length allows you to bend larger sheets of metal, which is ideal for production applications.

- High bending capacity: The high bending capacity allows you to bend thicker sheets of metal, which is ideal for heavy-duty applications.

- Hydraulic drive system: The hydraulic drive system provides smooth and powerful operation, which is essential for bending large and thick sheets of metal.

- Precision backgauge: The precision backgauge ensures that bends are accurate and repeatable, which is essential for producing high-quality parts.

- Heavy-duty construction: The heavy-duty construction makes the press brake durable and reliable, which is important for businesses that need to produce a high volume of parts.

If you are looking for a powerful, versatile, and accurate press brake for your sheet metal bending needs, the BETENBENDER 10 ft x 50 Ton Hydraulic Press Brake Model 10-50 is a great option. It is perfect for businesses of all sizes and is sure to meet your bending needs.

- ACCURACY

Every Betenbender machine is thoroughly inspected and tested.

1. Parallelism is maintained between bed and ram or at preset angle by using precision automatic leveling controls. Parallelism is maintained at +/-.002″ in low speed.

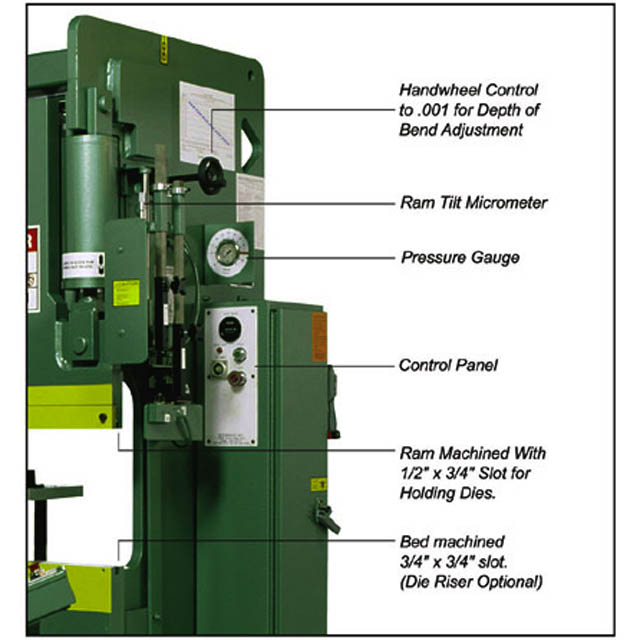

2. The ram bottom reversal point is controlled by precise limit switches referenced off the bed. This isolates housing deflections, which can interfere with its accuracy. - ENHANCED PRODUCTIVITY

Return speed and rapid advance facilitates high cycle rates. Operator control is simplified by slow and press speed, thus work spoilage is avoided. Rapid advance with automatic change. The point of speed change is fully adjustable by electric limit switch. Micrometer type tilt adjustment is graduated in .001″ increments permitting ram tilt adjustments up to 1/2″ in either direction. - ELECTRO MECHANICAL STROKE CONTROL is bed referenced. Bottom limit is manually set with a lead screw and displayed by an mechanical readout calibrated in .001″ increments.

- VERSATILITY

BETENBENDER’S press brakes have long full tonnage strokes, adjustable length and selectable speed combinations, adjustable height for short stroke, 2-speed standard and the optional 3- speed for adjustable low speed to prevent whip - ELECRICAL EQUIPMENT

Meets requirements of NFPA no.79, JIC and construction requirements of the latest ANSI B-11.3 Standards. Includes drip-proof, continuous duty 45 degree Celsius ambient hydraulic pump motor wired for 230 or 460 volt, 3 phase 60 hertz. - DEPENDABILITY

Self-lubricating replaceable non-metallic ways prevent galling and provide long service life. Cylinders are high-strength, all steel. To minimize wear and provide a superior oil seal, inside cylinder surfaces are honed to a mirror finish.

Compact, precision machined aluminum manifold incorporates off-the shelf components, minimizes piping and consolidates “O” ring mounted valves.

Quiet, vane type, constant volume pumps. In keeping with good hydraulic design practice, these energy efficient pumps are located outside the reservoir.

Filtration of contaminants as small as 10 microns is accomplished with intake and discharge filters. A built-in magnetic trap and air breather filter provides added protection against contaminants. Reservoir of large capacity facilitates effective heat dissipation. A fluid level gauge is provided. - CONTROL

Main Control Cabinet – NEMA 12 enclosures mounted in the right housing containing: magnetic non-reversing motor starter and 120 volt circuit.

Main motor START button and STOP button are illuminated.

RAM UP and RAM DOWN buttons.

RUN/JOG Switch.

Fusible disconnect. - MAINTENANCE

Clevis mounted cylinders eliminate cylinder binding by reducing the possibility of oil leaks from cylinder binding.

(Pins & bushings do not rotate under load, this reduces excessive wear) - MADE IN USA

STANDARD EQUIPMENT:

- Clamp Type Back-gauge-Manual Adjustable X,Y,Z

- NEMA Electrics

- All Hydraulic Fluid Included

- American Made Motor

- Hour Meter

- Lifetime Telephone Support @ No Charge

- Bottom Time Delay

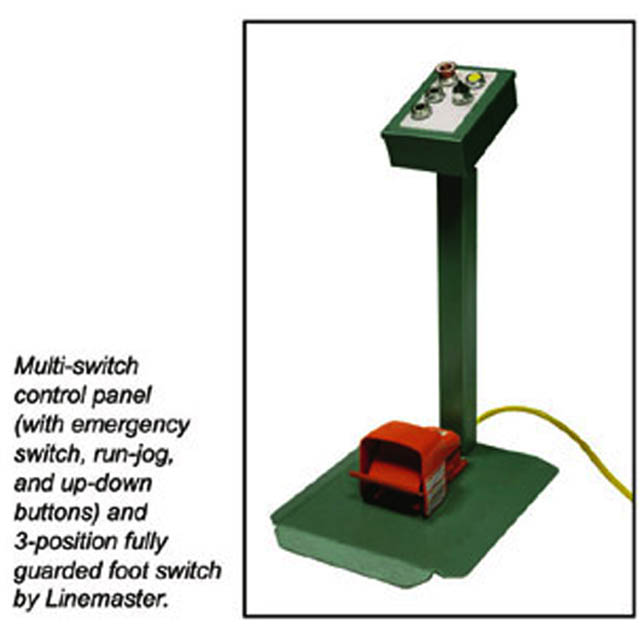

- Three Position Foot Pedal

- Depth Stop w/Digital Readout

- All Steel Construction

- Disconnect Switch

- Two-Speed Ram

- All Components Available from Local Suppliers

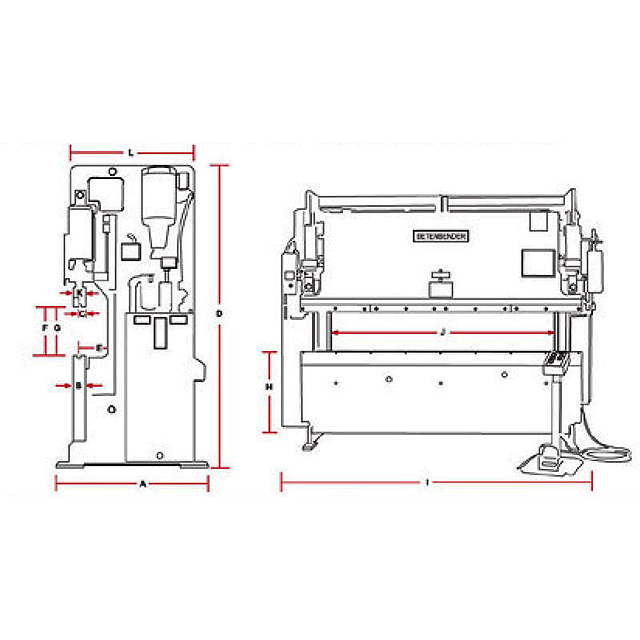

SPECIFICATIONS:

Maximum Tonnage: 50 Tons

Maximum Bending Length: 120″

Maximum Stroke Length: 8″

Open Height: 14″

Closed Height: 6″

Throat Depth: 8″

Distance Between Housings: 102-1/2″

Ram Repeatability: +/- .002″

Hydraulic Pressure: 2,500 lbs.

Hydraulic Oil Capacity: 31 gallons

Bed Height: 28″

Motor Horsepower: 10

Machine Weight: 11,000 lbs.

Machine Dimensions:

Overall Height: 104″

Overall Length: 135″

Overall Width: 45″

Specifications are subject to change without notice.

NOTE: Data is provided by the manufacturer.

WARRANTY: 1 YEAR – Parts