Description

- Akyapak has 54th years of experience and engineering expertise in a variety of products. Akyapak’s passion and dedication, which are reflected in every Akyapak machine in the market, to provide premium engineered solutions allow us to be more than your typical machinery manufacturer.

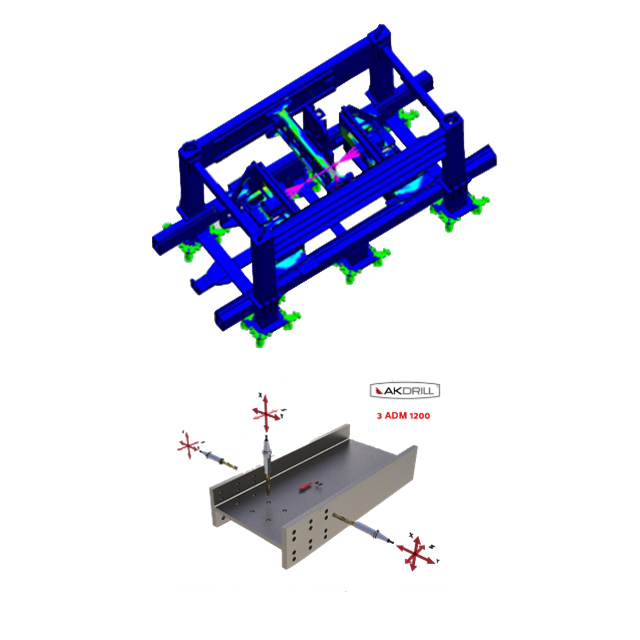

- FRAMES: The base frame of the machine consists of robust steel profiles and frames of motion axes consist of cast iron. The frame of the machine is designed with FEM simulation and thus mechanical solidity is guaranteed, optimizing suitable material selection, vibration and tension damping, and dimensional stability.

- SUPERIOR INDEPENDENT SPINDLE MOTION ABILITY IN 3 AXIS: The 3 ADM is equipped with sub-axis (z-axis) that enables independent control of spindles along 500 mm in the length of beam without repositioning it. After making a hole in the beam, there is no need to drive the beam to make another hole in the z-axis. Each spindle can move independently in 3 axes while the beam is stationary. This feature reduces processing time considerably and increases efficiency (approx. 3 times faster than the 2 ADM model).

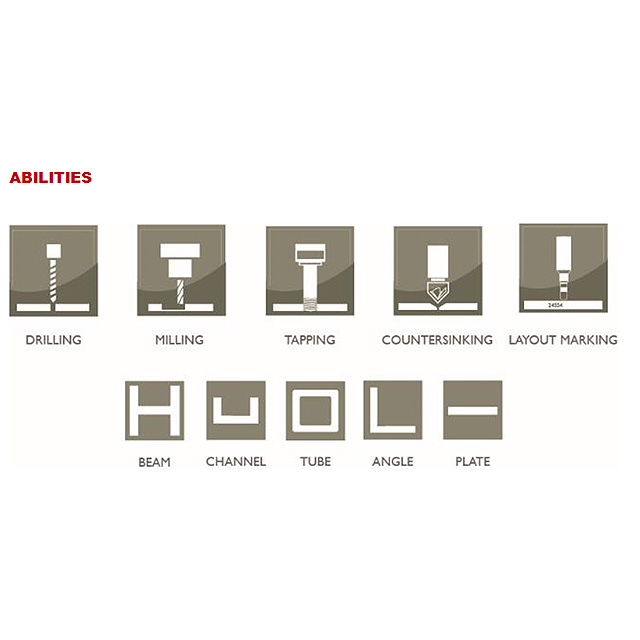

- The independent motion ability provides combining operations: While processing one side of the flange, it is possible to perform other operations (drilling, marking, tapping, milling, etc.) independently on the opposing flange and web.

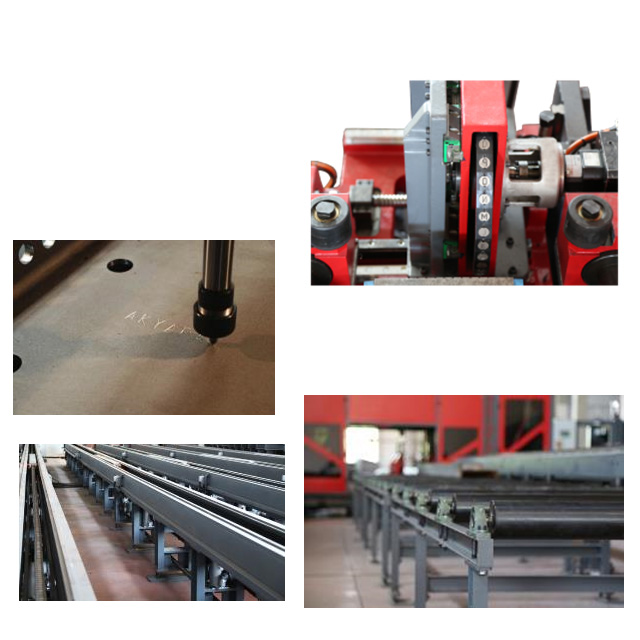

- ABILITIES: Drilling, milling, tapping, countersinking, layout marking, beam, channel, tube, angle, plate

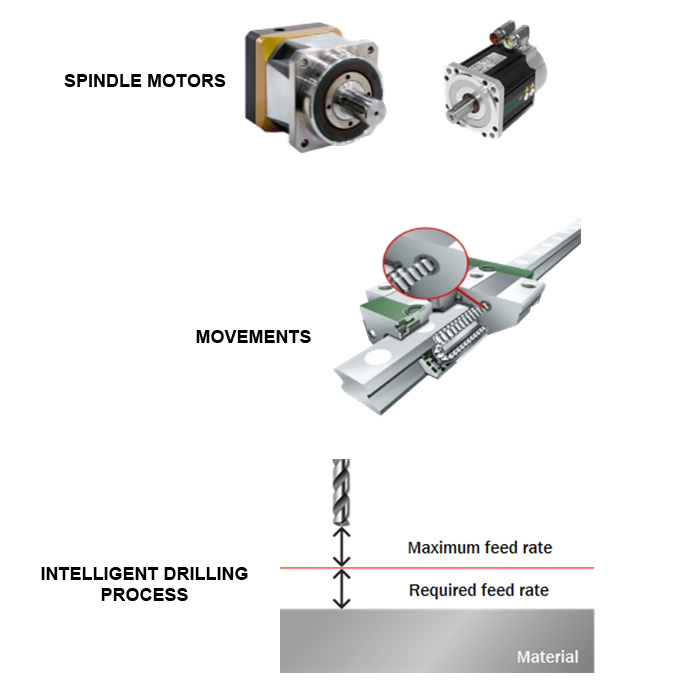

- SPINDLE MOTORS: The 3 ADM is equipped with servo motors that provide precise motion and includes 3 high speed 22 kW spindle motors

- MOVEMENTS: The roller linear guidance system, which provides high rigidity and a load carrying capacity, is used in all internal axis of the frame. This system supports all loads and moments from all directions

- Accurate positioning and high feed rates are guaranteed with servo motor driven ball screws

- FOR MORE INFORMATION SEE PRODUCT FEATURES TAB

SPECIFICATIONS:

Controller: Mitsubishi

Operating Range (mm):

Min. 200 x 80

Max. 1200 x 500

Drilling Units: 3

Drill Diameter (mm):

10 – 40 (Carbide and U-drill)

40 – 50 (U-drill only)

Thread Tapping: M12 – M24

Drill Holder: BT40

Spindle Speed (rpm): 50 – 3000 stepless

Spindle Power: 22kW

Spindle Torque: 280Nm

Tool Changer: 3 x 4

Weight per linear meter (kg/m): 600

Spindle positioning speed / returning speed: 5 m/min

Machine Weight: 12,303 lbs. (13000kg)

CALL US FOR CAPACITIES

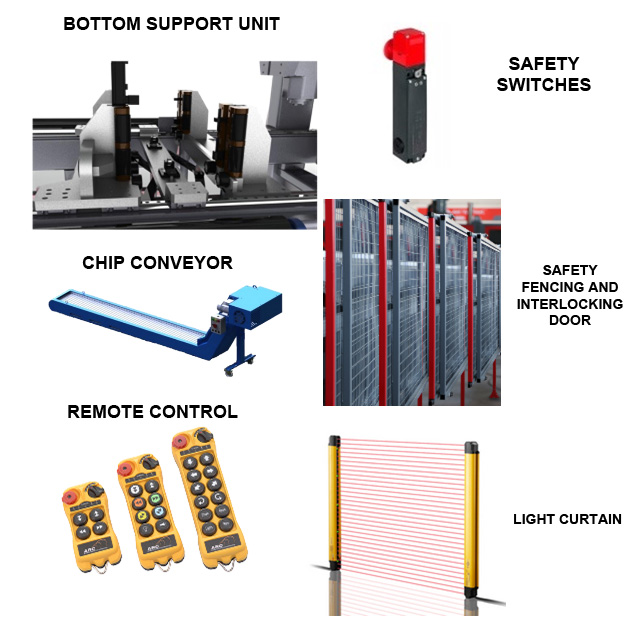

OPTIONAL ITEMS:

- AST 1200-1500 Bandsaw

- Chip Conveyor

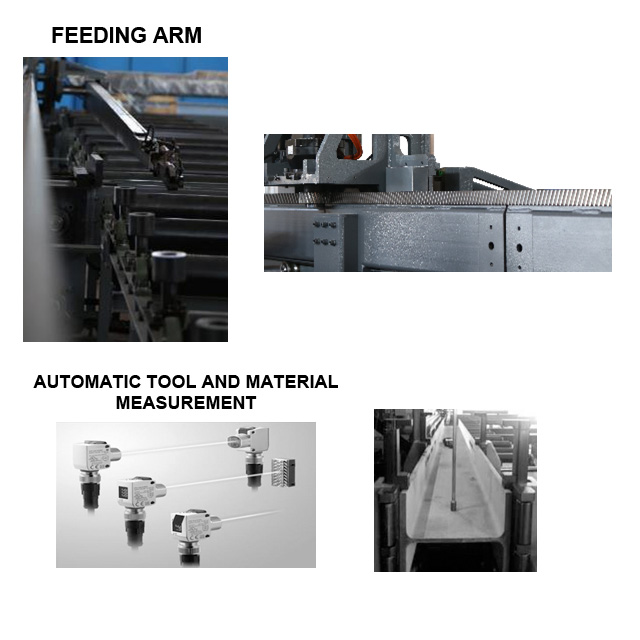

- Tool & Material Measurement

- Initial Drilling Pack

- Scribing Marking Unit

- Dot Marking Unit

- Lights Curtains

- Remote Control

- Online Connection HUB

- Additional Input Conveyor, [4mt (13ft)]

- Additional Output Conveyor, [4mt (13ft)]

- Automatic Loading System 40ft.

- Automatic Unloading System 40ft.