Description

- Standard Industrial is 100% Owned, Operated and Manufactured In The U.S.A.

- Full-Tonnage Throughout Stroke

- Typical 30+ Year Lifetime, Plus a Lifetime of Parts and Service Availability

- Solid, Non-Moveable Lower Beam Substantially More Rigid Than “Bed Level”

press Brakes - +,- .001″ Ram Repeatability

- Off-center loading Capability

- The Most Heavy Duty Press Brake Built In The U.S.A.

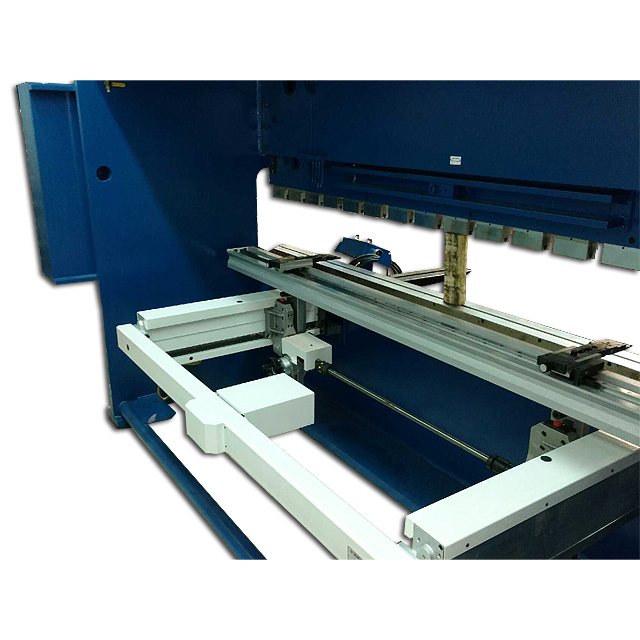

- Extremely Heavy-duty lower beams allowing the least amount of deflection.

Less Deflection = Longer Tool Life = More profitability - Precision mechanical in-line depth stop as back-up for any CNC control

- Single Cylinder Hydra-Mechanical Drive System

- New Manifold Based Hydraulic System

- *Contact Sheet Metal Machines if overall heights are critical.

- *Bed heights can be lowered with full machine pits

- *Contact Sheet Metal Machines for specifications on other size brakes

- FOR MORE FEATURES: CLICK HERE

SPECIFICATIONS:

MODEL: AB250-16

Tonnage Forming/Punching: 250/175

Bed Ram Length: 16′

Distance between Housings: 14′-5″

Open Height: 16″

Stroke Length: 8″

Closed Height: 8″

Below Grade: No

Approach Press Return: 20 h.p. 102-16-132

Throat Depth: 10″

Bed Width: 10″

Weight (prox. lbs.): 56,000

MODEL: AB250-20

Tonnage Forming/Punching: 250/175

Bed Ram Length: 20′

Distance between Housings: 18′-5″

Open Height: 16″

Stroke Length: 8″

Closed Height: 8″

Below Grade: Yes

Approach Press Return: 20 h.p. 102-16-132

Throat Depth: 10″

Bed Width: 10″

Weight (prox. lbs.): 88,000

*Contact Sheet Metal Machines if overall heights are critical.

*Bed heights can be lowered with full machine pits

*Contact Sheet Metal Machines for specifications on other size brakes

Specifications are subject to change without notice.

NOTE: Data is provided by the manufacturer.

WARRANTY: 5 YEAR – STANDARD Parts & Limited Labor

OPTIONAL ITEMS:

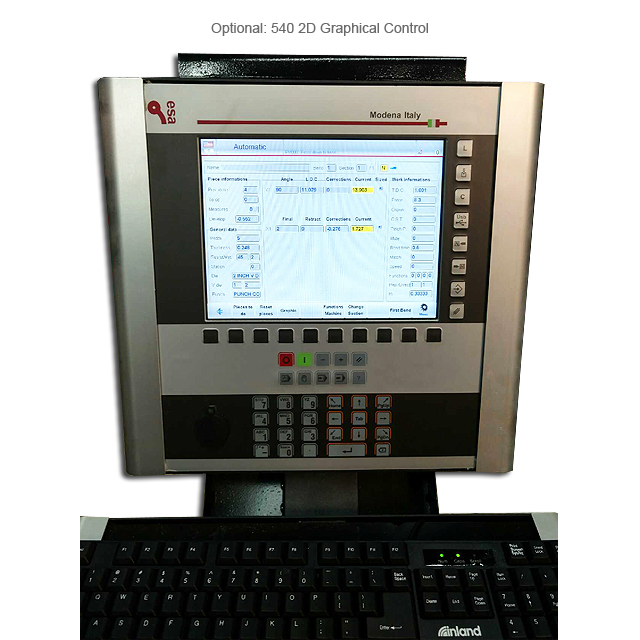

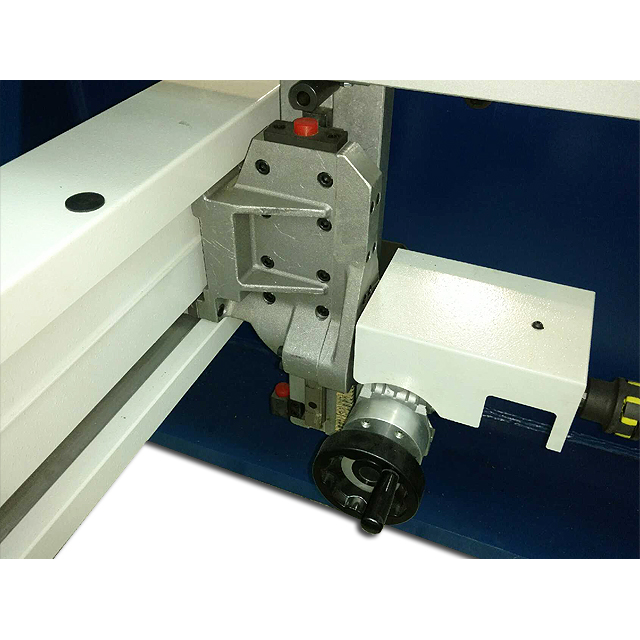

- Optional AUTOMEC CNC Control

- Easy to read mechanical ram level indicator and simple, precise ram level adjustment

- Counterbalance valve for punching and blanking to provide minimum shock

- Mechanical in-line depth stop to set the top limit, the speed change and a micrometer adjustable lower limit for the most precision bends

- All parts are readily available from your local suppliers-off the shelf parts for a lifetime

- All parts are listed in the press brake manual with detailed drawings and the original manufacturers part number so you can always find parts for your press brake

- Hydraulic reservoir with oil filter—Oil is not included

- Electric disconnect switch with magnetic starter—Simply run your power to the box

- Full tonnage the entire length of the bed and ram

- Full tonnage throughout the stroke—Full tonnage is developed anywhere in slow speed

- Both ends of ram tapped to accept your four way die lifters

- Incredibly simple and versatile hydraulic and electric controls

- Spring loaded die clamps for easy, quick die change

- Ram readily accepts standard or safety tang dies—Can optionally be fitted to accept European tooling

- Positive single cylinder hydra-mechanical drive system

- Electric anti-whip control for your operators safety

- Overload protection to avoid damaging the press brake

- Shock-less, quite operation

- Fully adjustable stroke, open height and speed change

- Extremely heavy duty, rigid, all steel unitized frame

- Lube fittings at all bearing points

- All liquid tight electrical components

- (2) 24″ support/gauging arms

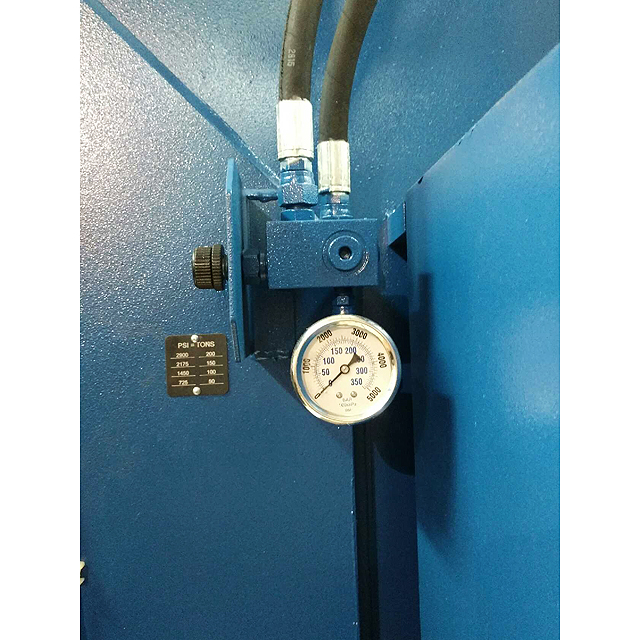

- Hydraulic pressure tonnage control with gauge

- Die groove in bed with set screws in front and rear of brake bed

- Portable 2 hand control station with normal-inch (jog) modes, E-stop and palm buttons

- All Standard Industrial press brakes are stringently designed to meet O.S.H.A and ANSI B11.3 standards as well come complete with J.I.C. type and U.L. listed electrical components