Description

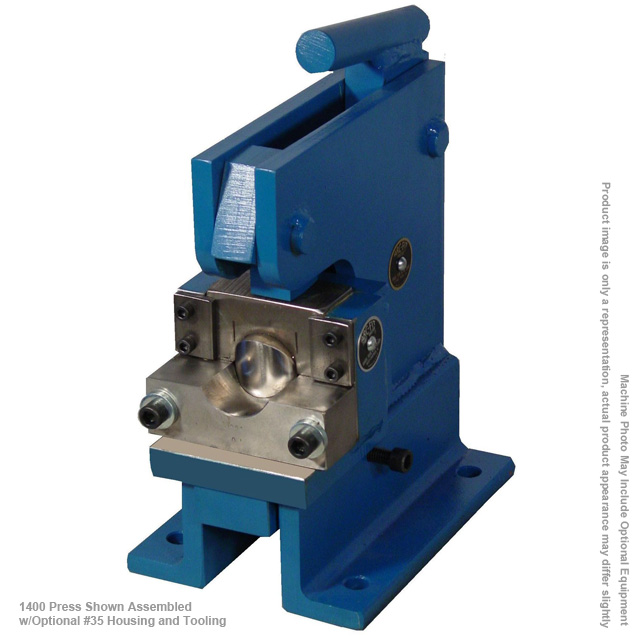

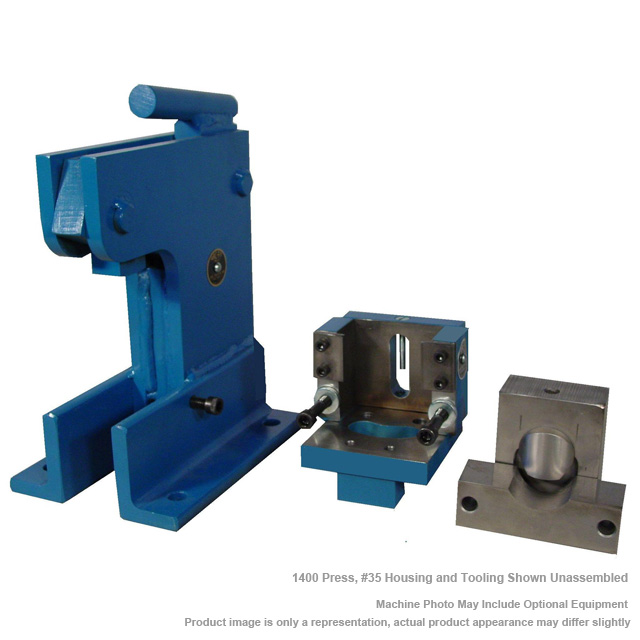

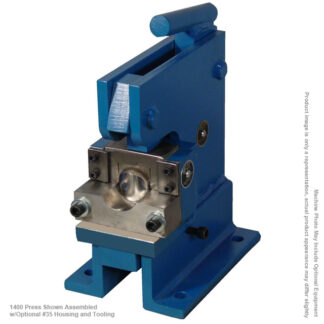

- If you want to notch pipe or notch tubing, our Arc-Fit hand press is the easy, low-cost and portable power option. Easy to bolt to a workbench or use in the field, our hand press accepts the Vogel #35 Housing and assemblies for up to 2″ x schedule 40 pipe & 2-3/8″ OD tubing. The Housing and Assemblies to be installed into the press are sold separately, see compatible products below.

- Even if you own Vogel’s Hydraulic Power Unit, many Vogel tool owners keep a hand press on hand to make notching on the job site easy and convenient.

SPECIFICATIONS:

SKU: 1400P

Tonnage: 8

Power Source: Manual

Specifications are subject to change without notice.

NOTE: Data is provided by the manufacturer.

WARRANTY: Limited

OPTIONAL ITEMS:

|

PART#

|

ITEM

|

PRICE

|

|

35

|

Arc-Fit Housing (Standard)

Max. Pipe Capacity: 2 in. Max. Tube Capacity: 2-3/8 in. Size – Left to Right: 4-1/2 in. Shut Height: 5 in. Stroke: 5/8 in. Tonnage: 8 |

$275.00

|

|

9202A

|

Arc-Fit Assembly:

For 1” x schedule 40 or thinner pipe (Approx 1-3/8” OD) |

$475.00

|

|

9203

|

Arc-Fit Assembly:

For 1-1/4” x schedule 40 or thinner pipe (approx. 1-5/8” OD) |

$475.00

|

|

9204

|

Arc-Fit Assembly:

For 1-1/2” x schedule 40 or thinner pipe (approx. 1-7/8” – 2” OD) |

$475.00

|

|

9205

|

Arc-Fit Assembly:

For 2” x schedule 40 or thinner pipe (2-3/8” OD) |

$475.00

|

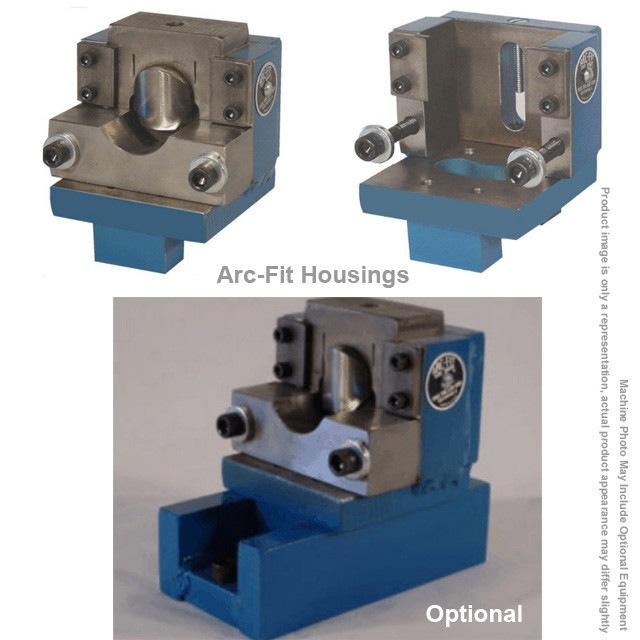

- The Arc-Fit Housing holds Arc-Fit Assemblies, which is the punch and die that produces the notch. To notch with our Arc-Fit tools, you need a Housing, and Assembly and a Press to provide power. The charts below indicate the maximum capacity of each housing. You may order many assemblies for each housing, or one housing for each assembly. This eliminates change over time and increase efficiency. Hardware and springs are included with each housing. The 201A Punch Press Adaptor is used to mount (1) Arc-Fit Housing in Vogel’s Hydraulic Press, we also offer a turntable that fits our Hydraulic Press that includes (3) housings.

- An Arc-Fit Assembly consists of three pieces, the round punch, square punch holder and rectangular die (tube rest). When worn, (typically 10,000 – 20,000 notches or more), you can send your punch and die to Vogel for sharpening, or simply replace just the worn items.

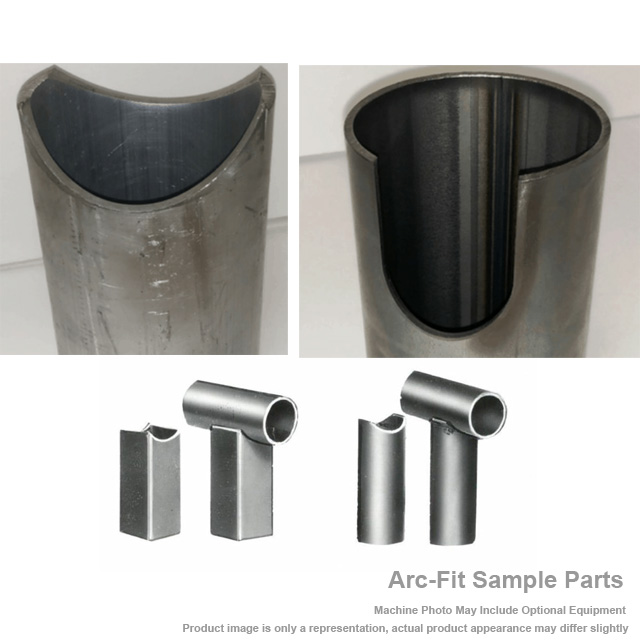

- How it works: The tube is slid onto the tube rest, over the punch. As the punch and punch holder are depressed, the punch notches the bottom wall of the tube. The tube is rotated 180º and the first notch, now on the top of the tube, is visually aligned with the scribe lines on the punch holder. The 2nd notch is made and the tube is ready for welding or brazing. These spring-loaded tools may be powered by most press brakes, ironworkers, punch presses. The #35 Housing can be powered by Vogel’s Hand or Hydraulic Presses. The #35 & #75 Housings can be powered by Vogel’s Hydraulic Press, see the charts below.

- In addition to notching a tube or pipe to fit the same size OD, we can make custom Arc-Fit assemblies. Examples of some of the many custom assemblies we can offer include:

- One size tube to fit a different size

- Custom shaped slots

- Notches with drainholes and more

Please contact us to discuss your specialized notching application.

- To notch pipe or notch tubing with our Arc-Fit system, you need a Housing, an Assembly for each pipe notching or tube notching application, and a Press to provide power. Some 90 degree Arc-Fit Assemblies can be powered by Vogel’s affordable and portable Hand Press. We also offer a 120V Hydraulic Power Unit. You can also install our Arc-Fit Housing and Assemblies in your own ironworker, press brake or punch press.

- How does an Arc-Fit Assembly work? Your tube or pipe is slid, horizontally, over the tube rest and onto the punch. The square punch holder functions as a stop, to insure every notch is the same depth.

- The press pushes the punch & punch holder downward, through the bottom wall of your material. The tube rest is also a cutting edge, supporting the underside of your material, preventing deformation. In most cases (round pipe fitting round pipe, for example), the material is rotated 180° and a second notch made. Simple scribe lines on the punch holder help line up the material for the second notch. Arc-Fit tools are designed for many years of use. We frequently hear from customers replacing tools that have been in service for 10, 15, 20 years and longer.

- Please Note: An Arc-Fit assembly can be used for the same OD, but thinner wall. For example, if you want to notch 1-1/2″ OD x 18 gauge, choose our 16 gauge assembly. Over the past eight decades, we have made thousands of custom Arc-Fit assemblies to suit specific applications. Examples of custom Arc-Fit assemblies include notching applications such as:

- A gauge not shown below

- One size notched to fit a different size

- Larger sizes, up to 6-5/8″ OD

- Square or rectangular tubes notched to fit round

- A notch to fit another tube with an drainhole

Please contact us to discuss your specific custom notching application. The list below is only our most popular notching tools that fit our #35 Housing (tubes and pipes that are 2-3/8″ or smaller OD). If you want to notch larger sizes (up to 6″ OD!), please contact us to discuss your specific notching applications. Assemblies for schedule 1″ through 2″ x schedule 40 pipe are offered at the lowest prices. Why? Because these are our most popular sizes, we build them in very large quantities and we are able to pass the savings on to you.

- **All Arc-Fits with an “A” designation after the part number (i.e. 9205A) are designed for mild steel or stainless pipe or tubing. Pipe that deviates from ASTM standards, with properties such as increased yield strength, or tubing made of HSLA materials high-strength alloys will exceed the capacity of our tooling and cannot be successfully notched with the Arc-Fit process. Use of our tools in these situations is NOT recommended and can result in tool failure and risk of injury.

- **It is the customer’s responsibility to ensure that the material is appropriate and suitable for Vogel tools. Material issues interfering with Vogel tool performance are not considered a manufacturing defect and will not be covered under Vogel’s product warranty. Returns will not be accepted for tools damaged by use with inappropriate materials.