Description

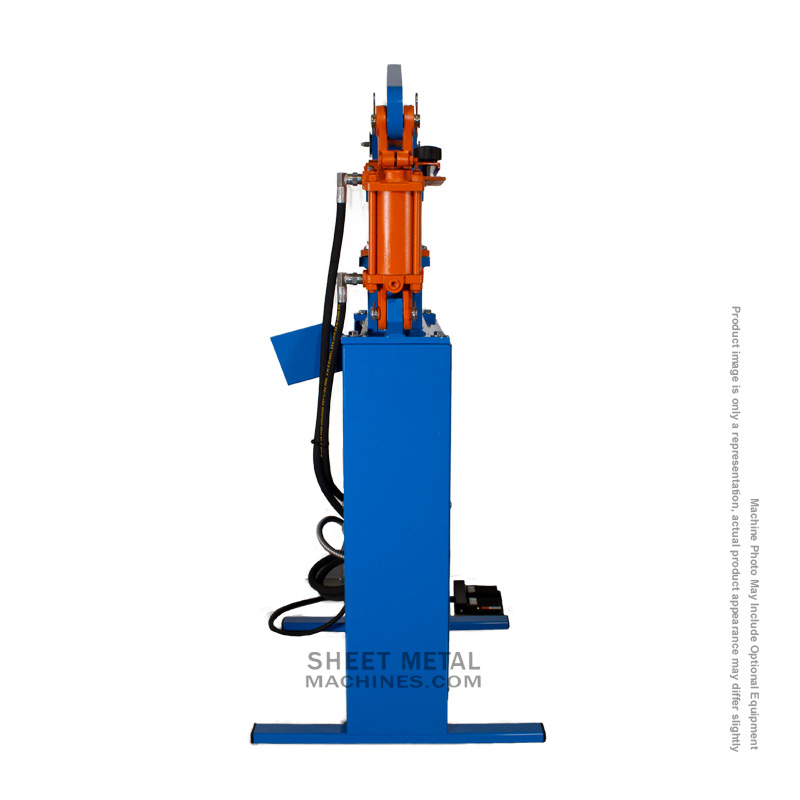

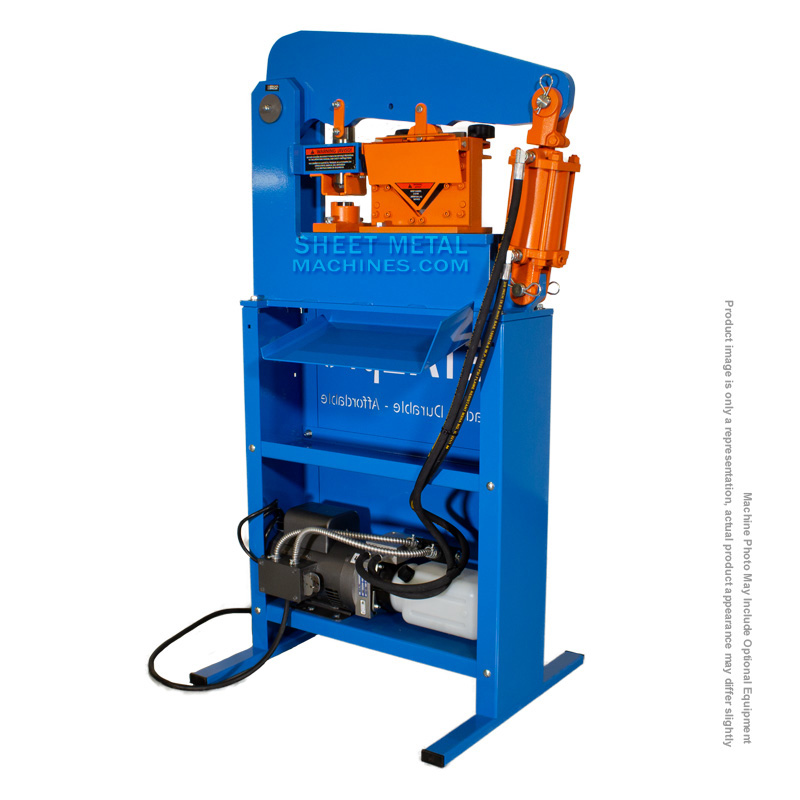

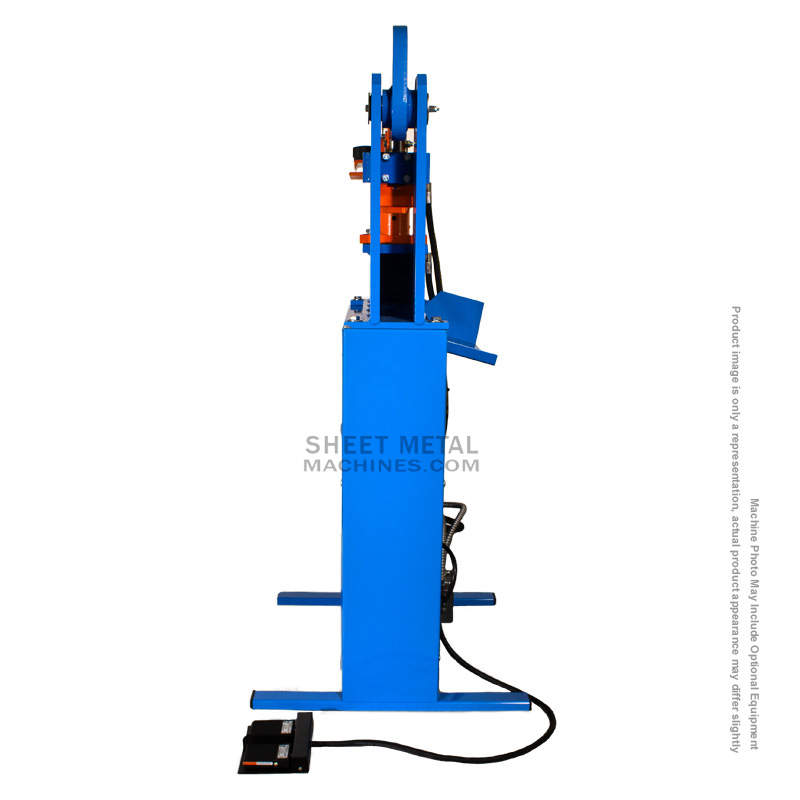

- The machine is ready with die holder, stripper, and punch retaining nut. The punch station can be used with a range of notchers, custom shape punching, and forming operations. The punch ram and retaining nut are machined and heat treated for long life.

- Shear handles flat bar, round, square, and angles in one quick set up. All wear parts and blades made from heat treated, high grade tool steel.

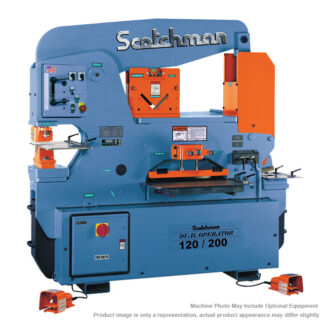

- The large 11 x 16″ power cavity delivers 20 tons at the shear. The outboard punching station delivers 40 tons at the punch and is designed to work with a variety of METALpro accessories:

- Round, square, oblong, and custom shaped punches and dies

- Heavy duty notcher

- Brakes

- Pipe notcher

- Wheel kit

- Lower cost alternative to higher priced equipment

- More fabricating capabilities per dollar spent on equipment

- Just as fast and accurate as expensive machines

- Works in any shop – plugs into standard 110V 20 amp outlet

- One year warranty

- Punch capacity of 40 tons

- 3-3⁄4″ throat depth

- 2″ die holder, punch retaining nut and stripper

- Power cavity with 3-in-1 shear

- Guarding complies with ANSI B11-8 standards

- Meets American National Safety Standards for ironworkers

- Optional brakes and custom tooling sold separately

- All in one ‘fabrication shop’ with capabilities in:

- Punching

- Forming

- Shearing

- Pressing

- Notching

- Pipe notching

- Bending

- MADE IN USA

SPECIFICATIONS:

SPEED

Strokes per minute: approximately 6-8

Motor: 110V, 1-1/2 horsepower

Capacity: 40 Tons

Throat Depth: 3-3/4″

Punch: 40 Ton max capacity

SHEAR

Flat bar: 3/8″ x 4″ and 1/4″ x 6″

Angle: 1/4″ x 3″ x 3″

Rod: 3/4″

Square: 5/8″

Hydraulics: 2900 PSI

Oil capacity: 1.5 US gallons

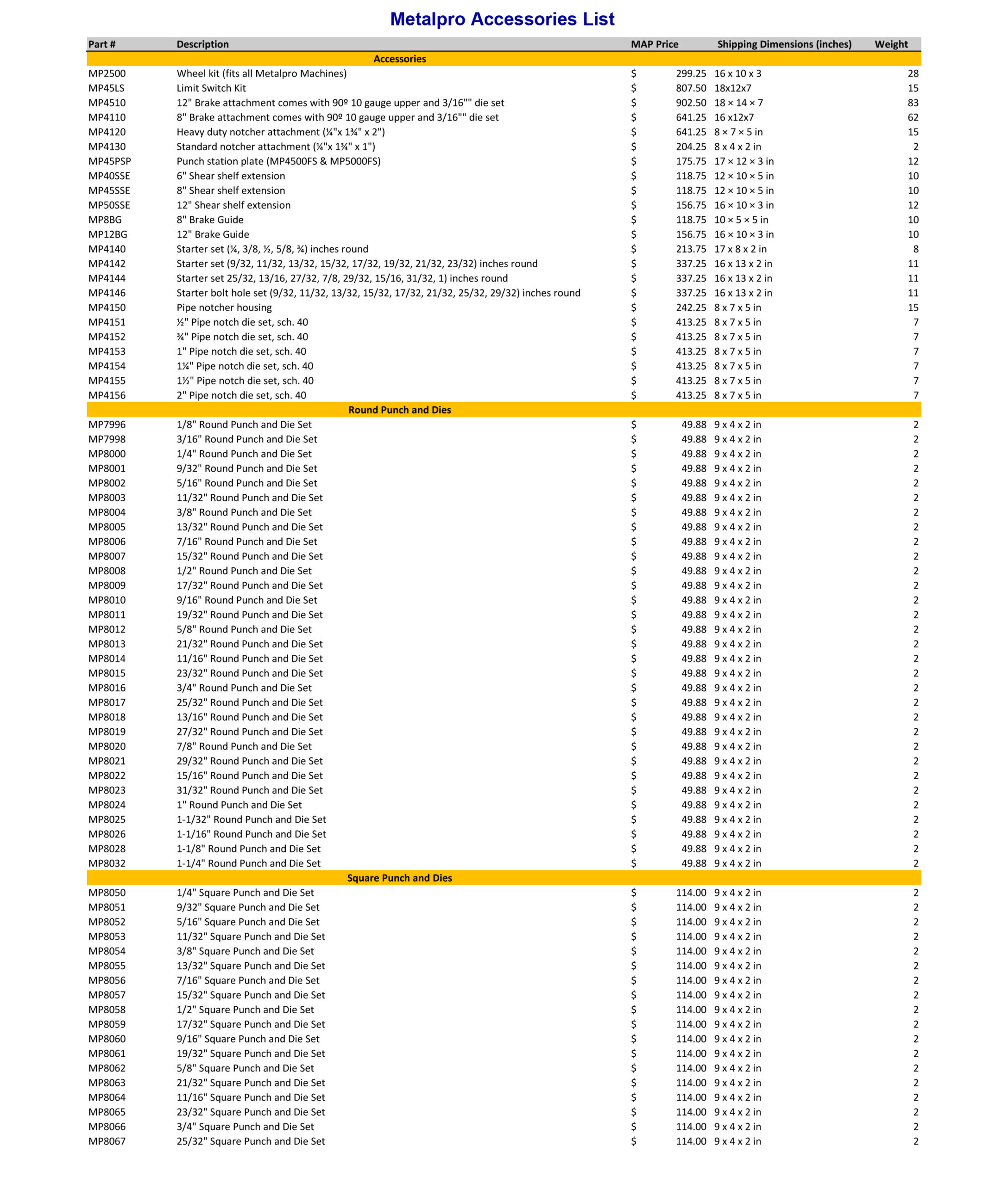

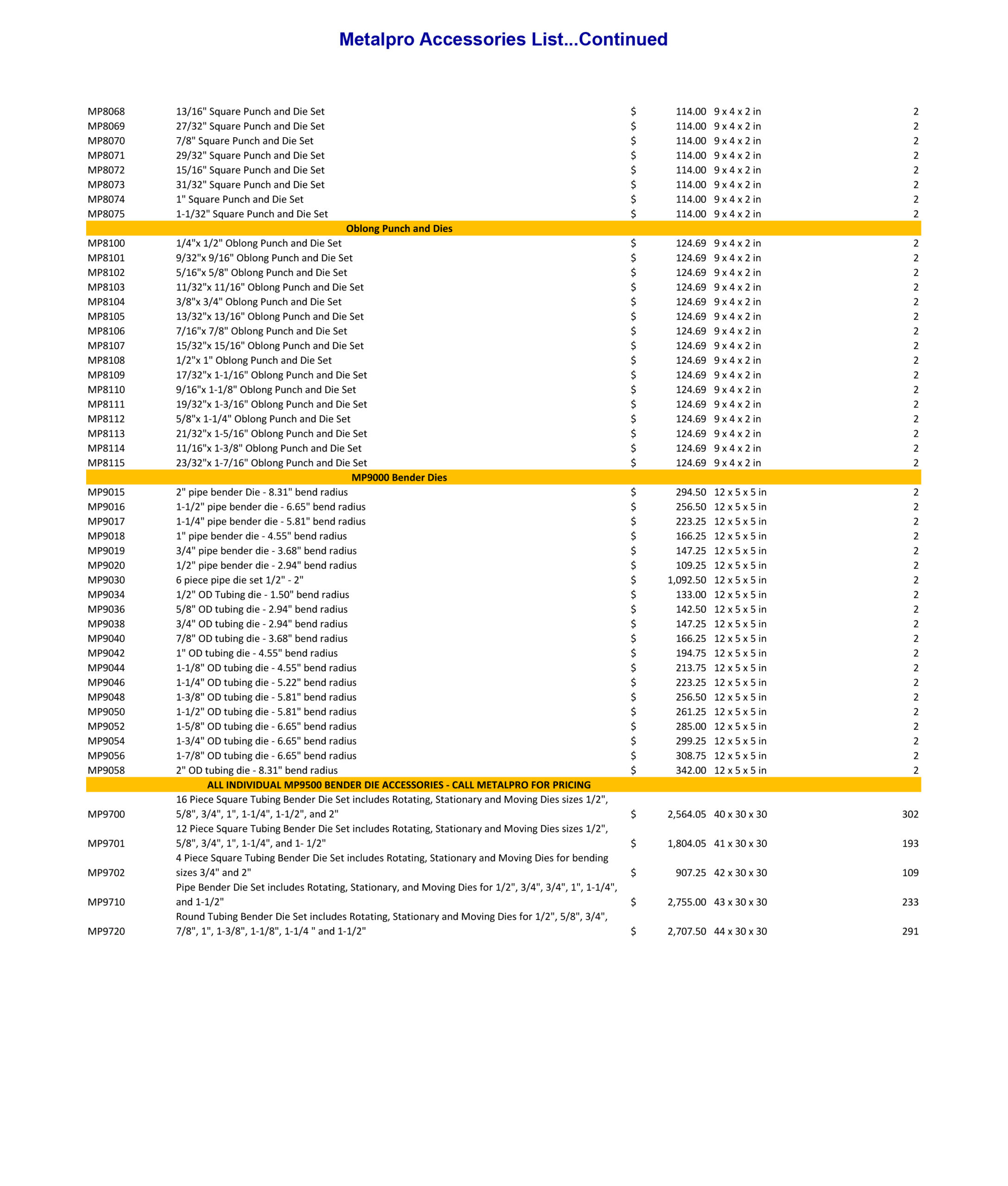

ACCESSORIES

Brake: 20 Tons

Notcher: optional 1/2, 3/4, 1, 1-1/4, 1-1/2, 2 inch sch. 40

Picket Tool optional: 1/2, 5/8, 3/4 inch

Pressing: Custom tooling available

FRAME DIMENSIONS

Width: 24″

Height: 58″

Length: 30-1/2″

Weight: 435 lbs.

OPTIONAL ITEMS:

Optional brakes and custom tooling sold separately

MP45LS – Sensor Controlled Limit Switch Kit, 5 lbs., 24 x 6 x 2 in.: $950.00

- MP45LS – Limit Switch Kit: The MP45LS is a sensor controlled limit switch that automates your Metalpro Ironworker. The two sensors (one return sensor, and one stop sensor) reads the top and bottom of the arm. The sensors allow for micro adjustments for precise stroke control. This ensures the exact stroke height that you are looking for whether forming/bending, punching or shearing with your Metalpro ironworker.

- Punching/Shearing – Control your stroke height with just one press of the included foot pedal, speeding up your punching and shearing operation, saving you time and money.

- Forming/Bending – The stop and return sensors allow you to form within a quarter of a degree, helping with repeat air bends, taking the guesswork out of it.

MP2500 – Wheel kit (fits all Metalpro Machines): $299.25

For Full List of Metalpro Accessories – See Accessories Price List (See Photo Gallery)

Specifications are subject to change without notice.

NOTE: Data is provided by the manufacturer.

WARRANTY: 1 YEAR – Parts