Description

- Our 70 ton press brake are equipped with a three axis ESA Control. This is a Taiwan quality machine, designed in the USA. With it’s rugged steel framework, quality hydraulic and electronic components, makes this press brake a great addition to any shop.

- ISO 9001 certified

- Meet OSHA and CE safety standard

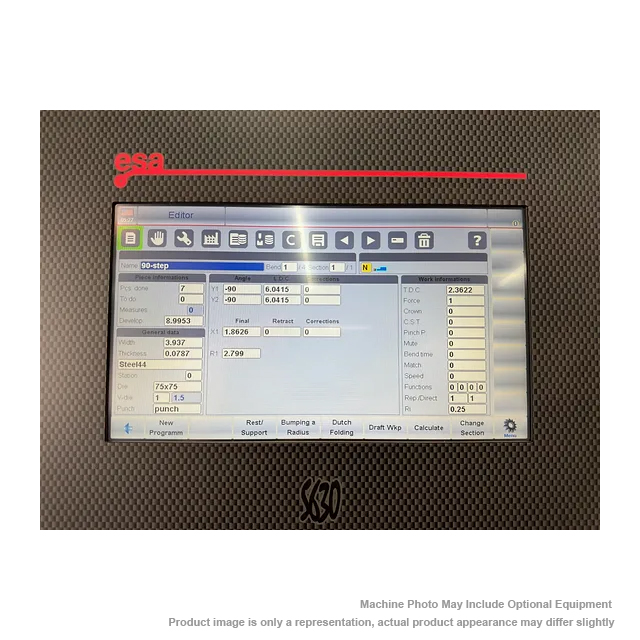

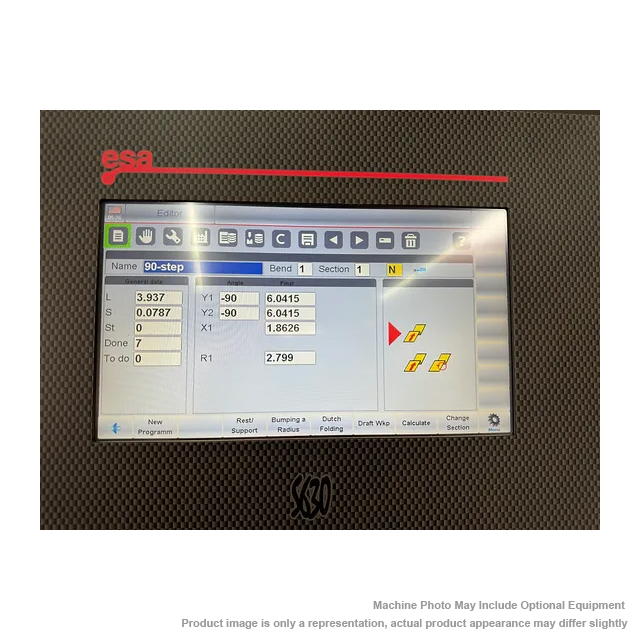

- ESA (Italy) Model 630, 3 Axis CNC Controller

- Die library, offline programming, stores thousands of programs

- Programmable Angle/ Angle Correct

- 10” Touch screen

- 3 Axis CNC Graphic Controller

- Y axis Ram with high precision linear encoder

- X servo Back gauge

- R programmable Back gauge height

- Line by line coding

- 2D Graphic Drawing Mode

- Bend Sequence Optimization for collision detection

- Spread Length Calculation

- Germany Rexroth hydraulic system

- Yaskawa Servo motor and Drives

- Schneider electrical components

- All steel construction for maximum rigidity

- Hydraulic logic system centrally located and quiet

- Safety type foot pedal with handle and E-stop switch

- Safety 24V low voltage & overload protection

- One year industrial warranty for parts

- DISCLAIMER: Please note this machine is incompatible with the use of a rotary phase converter. Any attempt to purchase, install, or employ one, whether carried out by you or a professional service company, will automatically void the warranty. It is crucial to understand that any such actions are entirely the responsibility of the buyer.

- This disclaimer is intended to clearly convey that the utilization of a rotary phase converter to power or operate this machine is not supported.

STANDARD EQUIPMENT:

- ESA (Italy) Model 630, 3 Axis CNC Controller

- (2) 24″ front support arms, Quick Release for easy positioning

- Quick release segmented (American Style Tooling) punch holder

- Full Length Gooseneck Punch HRC 50 (Punch is rated for 10 gauge and lighter .062” radius punch) Additional Tooling may be required for thicker materials and purchaser’s specific products/parts – Ask your dealer for custom tooling quotes)

- Full Length Vee Die with 6 assorted sizes HRC 50

- Lntech Light Curtain System

- Side and Back Safety Fence

- Movable Foot Pedal with Estop meet OSHA safety standard

SPECIFICATIONS:

Maximum pressure: 70 Tons

Bending length capacity: 80″ (6′ 8″)

Distance between uprights (housing): 63″

Ram Stroke travel: 6″

Cylinder travel adjustment, max: 3-1/8″

Table width: 6″

Distance between table and ram: 15-1/4″

Max stacked tooling height: 8-1/2″

Throat Depth: 10″

Back Gauge Distance: 24″

Back Gauge Repeatability: .0039″

Y Axis Repeatability: .0039″

Approach speed, inch / second: 3.14″

Working speed , inch / second: 0.35″

Return speed , inch / second: 2.36″

Main motor: 7-1/2 HP, 3-phase, 208V or 220V (please specify)

Servo motor for back gauge: 1 HP, 220V or 208V, 3-phase

Servo motor for bending angle setting

1/2 HP, 220V or 208V, 3-phase

Amperage draw: 30 Amp

Hydraulic oil tank capacity: 52 Gal.

Recommended Oil: Hydraulic oil Shell# 68HD

Machine weight: 8,650 lbs.

Machine size, L x W x H: 103 x 63 x 87 in.

Machine shipping dimensions: 109 x 66 x 98 in.

OPTIONAL ITEMS:

- For ¼” tooling: Need single V die holder ………..call for pricing

- 4’ of punch and 2.5” single V Die , Flame hardened with safety tang….. call for pricing

- On-site training, one day………….. call for pricing

Specifications are subject to change without notice.

NOTE: Data is provided by the manufacturer.

WARRANTY: 1 YEAR – Parts