Description

SPECIFICATIONS:

|

MODEL

|

BEAMX 1200

|

|

Control Panel

|

FS 31i-B Plus 21.5″ Color LCD Touch Panel

|

|

Number of Drilling Units (Horizontal)

|

1 Horizontal Drilling Unit

|

|

Drilling Diameter

|

3/8″ – 2″

|

|

Spindle Speed

|

Infinitely adjustable, 50-4000 rpm

|

|

Spindle Motor Power

|

20 HP, 280 Nm

|

|

Motion Transmission System

|

Preloaded Ball Screws – Nut System

|

|

Automatic Tool Changing Unit

|

6-Station ATC Unit for Each Spindle

|

|

Conveyor Length

|

46 ft

|

|

Central Lubrication System

|

Standard

|

|

Tool Cooling System

|

MQL (Minimum Quantity Lubrication)

|

|

Weight Per Linear Meter

|

1653 lb

|

|

Tapping Tool for Each Drilling Axis

|

M10-M24 (with Special Set)

|

|

Beam Width

|

47″

|

|

Beam Height

|

20″

|

|

Tool Holder

|

BT 40 (with Coolant Channels)

|

|

Workpiece Movement

|

Servomotor + Planetary Gearbox

|

|

Beam Measurement System

|

Standard

|

|

Miter Band Saw Integration

|

Optional

|

|

Machine Dimensions

|

7 x 23 x 10 ft

|

|

Scribe Marking

|

Standard

|

|

Chip Conveyor

|

Optional

|

CUTTING PROFILES SIMULATION:

|

FEATURE

|

Lantek Flex3D SteelWork

|

Lantek Flex3D Steel Work SD Plus

|

|

Single Nesting

|

Yes

|

Yes

|

|

Multi Nesting

|

No

|

Yes

|

|

Inventory Management

|

No

|

Yes

|

|

Standard/Optional

|

Standard

|

Optional

|

|

DSTV Importer (Standard)

|

Yes

|

Yes

|

|

SAT and CAM Importer (Optional)

|

Yes

|

Yes

|

PROFILES:

|

PROFILE TYPE

|

Minimum Size (mm)

|

Minimum Size (inch)

|

Maximim Size (mm)

|

Maximim Size (inch)

|

|

Equal Angle

|

80 x 80 x 8

|

3.15” x 3.15” x 1/3”

|

250 x 250 x 28

|

9.84” x 9.84” x 1.1”

|

|

U-Channel

|

80 x 45 x 6

|

3.15” x 1.77” x 1/4”

|

400 x 110 x 14

|

15.74” x 4.33” x 0.55”

|

|

Wide Flange Beam (HEA)

|

96 x 100 x 5

|

3.77” x 3.93” x 0.19”

|

990 x 300 x 16.5

|

38.9” x 11.8” x 0.64”

|

|

European I-Beam (HEB)

|

100 x 100 x 6

|

3.93” x 3.93” x ¼”

|

1000 x 300 x 19

|

39.3” x 11.8” x 0.74”

|

|

European I-Beam (HEM)

|

120 x 106 x 12

|

4.7” x 4.1” x 0.47”

|

1008 x 302 x 21

|

39.6” x 11.8” x 0.82”

|

|

H Welded Profile

|

—

|

—

|

1200 x 500 x 50

|

47.2” x 19.68” x 2”

|

|

I-Beam (IPE)

|

80 x 46 x 3.6

|

3.14” x 1.81” x 0.14”

|

770 x 268 x 15.6

|

30.3” x 10.5” x 0.61”

|

|

I-Beam (IPN)

|

80 x 42 x 3.9

|

3.14” x 1.65” x 0.15”

|

550 x 200 x 19

|

21.6” x 7.87” x 0.74”

|

|

Full Square Bar

|

100

|

4″

|

1200

|

47.2″

|

|

Square Tube

|

80 x 80

|

3.15” x 3.15”

|

500 x 500

|

19.68” x 19.68”

|

|

Rectangular Tube

|

40 x 80

|

1.57” x 3.15”

|

1200 x 500

|

47.2” x 19.68”

|

Note: The width is 4 in. if welded extension is not acceptable.

FEATURES:

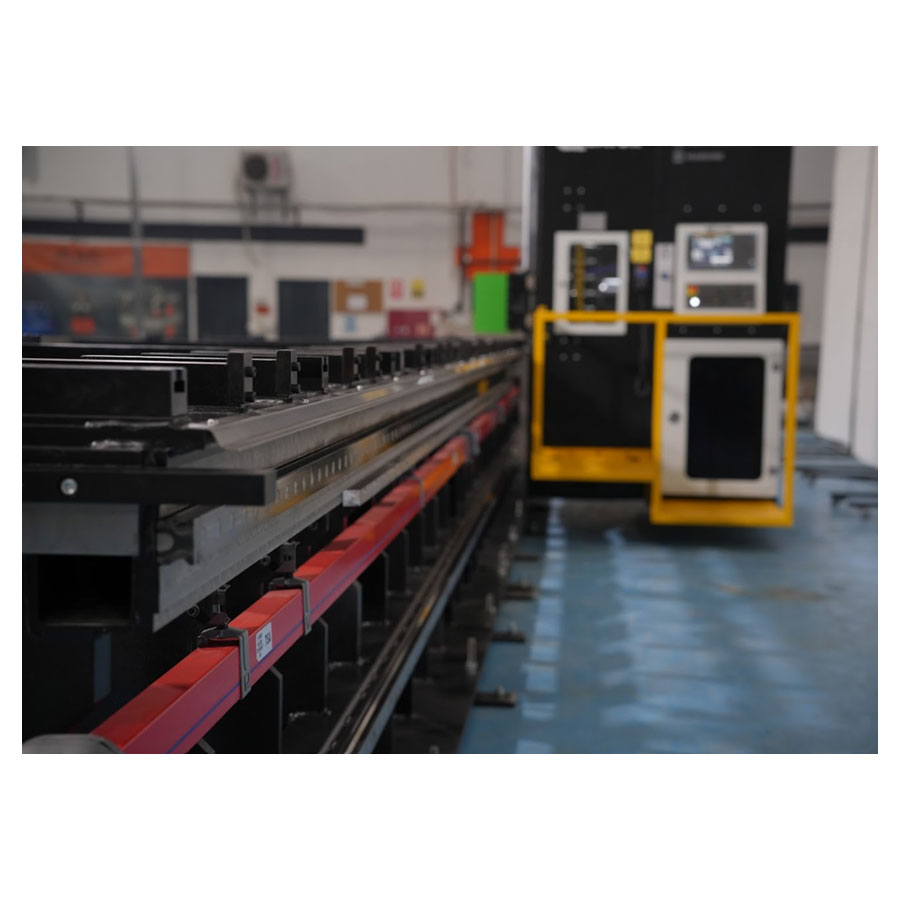

- 46′ Long All-in-One Drilling Machine, 10” SubX (z-axis) and 20 hp spindles

- ATC – AUTOMATIC TOOL CHANGER (Standard)

- The machine is equipped with one automatic tool changing unit for each spindle. Each unit has four stations for different tools.

- The ATC system allows for fast and automatic tool changes, eliminating manual intervention and minimizing machine downtime.

- Capacity: 6 tools

- Spindle MOTOR

- The machine is equipped with servo motors for precise motion control and includes one high-speed spindle motor.

- The roller linear guidance system, providing high rigidity and load-carrying capacity, is used in all internal axes of the frame. This system supports loads and moments from all directions, ensuring optimal performance.

- Key components include:

- INA – Schaeffler Group (Germany) products for high-quality linear guidance.

- Servo motor-driven ball screws for accurate positioning and high feed rates.

- Feeding Arm components sourced from top manufacturers, including:

- Atlanta (UK)

- Schneeberger (Germany)

- WHM Herion (Germany)

- FRAMES: The base frame of the machine is constructed from robust steel profiles, while the motion axes frames are made of cast iron. The frame is designed using FEM (Finite Element Method) simulation, ensuring mechanical solidity by optimizing material selection, vibration and tension damping, and dimensional stability

- HYDRAULIC POWER SYSTEM (Standard): The 10 hp (total) hydraulic power unit generates high working pressure. The hoses and connections are designed to withstand high-pressure hydraulic circuits.

- Easy intervention and troubleshooting are facilitated by the hydraulic power unit, sourced from Parker (USA), Brevini (Italy), or equivalent.

- ELECTRICAL COMPONENTS (Standard): All critical electrical components in the system, including thermal protectors, contactors, relays, and more, are selected from high-quality products by well-known brands.

- To ensure optimal performance, all components and drivers are maintained at a constant temperature within the electrical enclosure.

- MATERIAL CLAMPING SYSTEM (Standard): The beams are clamped on the horizontal plane between rollers hydraulically, and vertical clamping is achieved hydraulically using pressure arms. To prevent deflections and vibrations during drilling operations, 16 hardened rollers come into contact with the beam on both sides.

- MQL – MINIMUM QUANTITY LUBRICATION (Standard): MQL minimizes environmental impact by using a 100% natural, vegetable oil-based mixture, eliminating the need for cleaning coolant liquids. This almost-dry processing allows the machine to move directly to the next operation (e.g., welding, marking) without the delay of coolant disposal.

- The system includes a 5-liter coolant capacity for internal tool cooling and 2 liters of lubricant for machine installation.

- INTELLIGENT DRILLING PROCESS (Standard): The spindle speed is adjustable steplessly. The spindle approaches the material at maximum feed rate until it reaches the safety distance, after which the feed rate is reduced to ensure a safe and efficient drilling cycle. Mac Drilling recommends using Kennametal KSEM series tools.

- AUTO-LUBRICATION (Standard): The central lubrication system consists of a grease pump and both main and intermediate distributors. This system automatically lubricates 54 lubrication points on the machine periodically. The system is designed to handle up to 250 bar oil pressure and has a 1-liter capacity. Thanks to the auto-lubrication system from SKF (Sweden), all movable components operate smoothly, increasing their lifespan.

- SAFETY SWITCHES (Standard): To ensure a safe working environment, the machine automatically stops if the doors are opened during production.

- SAFETY FENCES and INTERLOCKING DOORS (Standard): A safety fence is available upon request to prevent access to dangerous areas. The safety fence comes in various types and dimensions.

- The interlocking door is integrated with the safety fencing system. If the sensor detects that the interlocking door is opened, all systems in the relevant zone will be shut down immediately for safety.

- REMOTE CONTROL (Standard): The remote control allows the operator to monitor and inspect the process safely without the need to move around the machine.

Note: The remote control may vary depending on the selected options. - CE AND INTERNATIONAL STANDARDS

- All Gator Machines comply with CE regulations and meet the following international standards:

- Related Directives and Annex: Machinery Directive 2006/42/EC/Annex VIII

- Related Standards: EN ISO 12100:2010, EN 12717:2001+A1:2009, EN 60204-1:2006/AC:2010

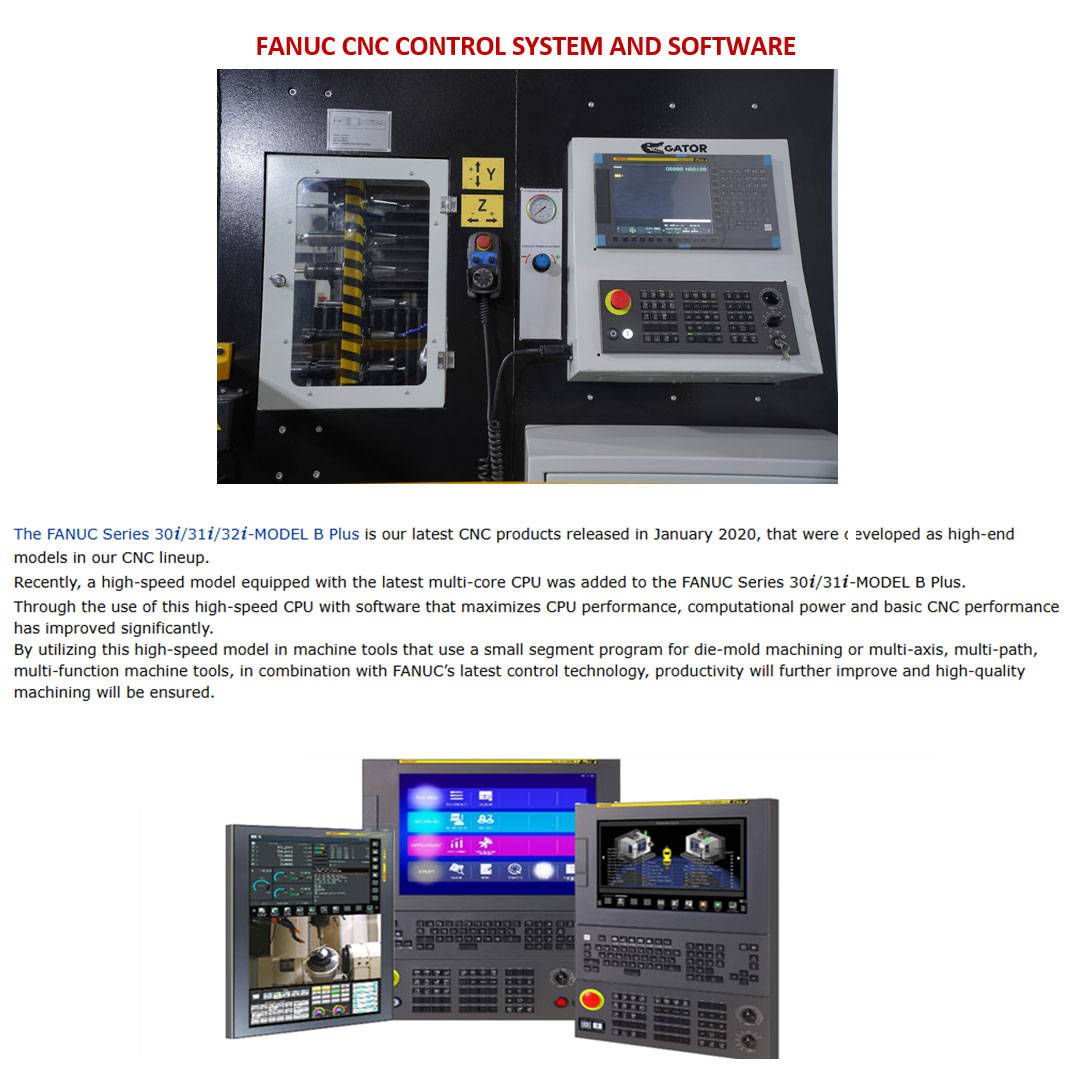

- FANUC CNC CONTROL SYSTEM AND SOFTWARE

The machine is equipped with a Fanuc CNC control system, known for its precision, reliability, and advanced capabilities. This system provides seamless control and ensures optimal performance for all machining operations.

Key features include:- User-friendly interface: The intuitive Fanuc software interface allows operators to easily program and control the machine, enhancing productivity.

- Real-time monitoring: Fanuc’s system provides real-time feedback and performance tracking, ensuring consistent accuracy throughout operations.

- Customization options: The software offers a range of customizable parameters to suit various applications and material types, allowing for flexibility in production.

- Integrated diagnostics: Fanuc’s built-in diagnostics system quickly identifies and resolves any issues, minimizing downtime and optimizing efficiency.

- Data storage and retrieval: The Fanuc CNC system stores all project data, including settings and material dimensions, for quick and easy retrieval during future operations.

- PROGRAMMING SOFTWARE

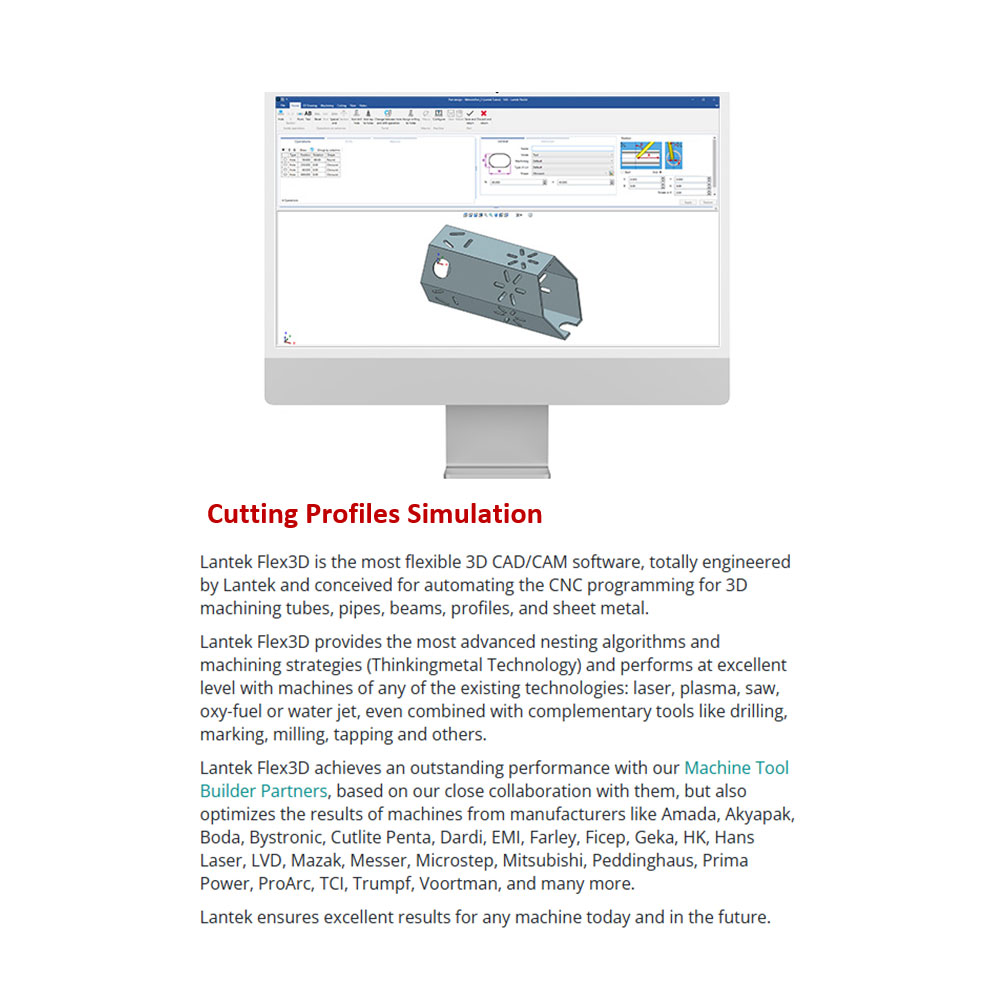

- Lantek Flex3D SteelWork is a new module in the Lantek Flex3D product family, specifically designed for the design and machining of standard profiles. It is a stand-alone product that does not require any additional Lantek software. With over 20 years of experience in the sheet metal market, Lantek has created a powerful offline design and programming system for profile cutting machines, supporting both sawing and drilling operations.

- Easy and Flexible Design

Lantek Flex3D SteelWork allows for 3D design in an intuitive and simple way, offering a real-time preview of the results when drilling and sawing the profile on the machine. The system is highly flexible, enabling the creation of any type of standard profile. It is a parametric system that allows users to modify any previous operation, including changing the initial parameters of each profile (e.g., enlarging, shortening, etc.).

Once the design is complete, users can simulate the machine’s head movement in 3D, displaying each machining operation along the profile or tube (profiling, drilling, sawing). The software also allows for the generation of NC files, which can be sent directly to the machine. Lantek Flex3D SteelWork is adaptable to work with any profile or tube machine. - Technical Characteristics

Lantek Flex3D SteelWork simulates the exact profile and 3D process for each operation, minimizing the possibility of errors.

The software enables users to create standard sections, eliminating the need to duplicate entry information when creating profiles. Users only need to select a standard base section, then input the length and material. The system is built on database technology, providing complete management of various profile products and remnants, ensuring quick access and efficient data handling. - Cutting Profiles Simulation

- Lantek Flex3D SteelWork allows users to simulate each profile operation, including drilling, cutting, and the work zone. The software automatically generates the NC file for each machine based on the machined contours of each profile.

- Lantek Flex3D SteelWork can detect potential collisions and provides the user with tools to manually modify them. The system will automatically avoid collisions where possible, and if any occur, they will be highlighted during the simulation phase. Users can zoom, move, rotate, and adjust the axis positioning of the profile during the simulation view for better inspection. Additionally, operators can create drawings in Tekla and transfer them to Lantek Flex3D SteelWork for further processing.

OPTIONAL ITEMS:

- Lantek Flex 3D SteelWork SD Plus Module

- SAT Importer

- CAM importer

- 1 set of starter tool set

- Scribe/marking tool 3,000 rpm

- Scribe/marking tool with Air 20,000 rpm

- Light Curtains

- AUTOMATIC TOOL AND MATERIAL MEASUREMENT (Optional)

The machine features independent measurement systems that automatically measure the material’s length, width, and height. The operator inputs the material type and dimensions into the program, and the software determines how many points the material height measurement will be performed.- Flanges and web heights are measured automatically with a measurement probe.

- When the beam is clamped horizontally, the width of the beam is measured automatically using a measurement probe.

- Material length is measured using a laser sensor at the exit of the machine.

- The software stores these dimensions to calculate the required real dimensions, ensuring more accurate results when starting the process.

Additionally, the tool length can be measured automatically by a laser sensor when a new tool is placed in the tool changer.

By automatically measuring material dimensions and drill length, the system saves time and enhances operational safety.

- SCRIBING MARKING TOOL (Optional)

The machine is equipped with a scribing tool for marking on 4 surfaces of beams.

The markings are of high quality and remain readable even after processes like painting or blasting. - For more details, please feel free to ask.

- LIGHT CURTAINS (Optional)

Light curtains are provided upon request to detect approaches in a dangerous area. When a light curtain is crossed, all systems of the relevant area will be shut down immediately. - DSTV, SAT and CAM File Importing (Optional)

Lantek Flex3D SteelWork can import data generated by third-party CAD systems used for designing structures, such as DSTV, SAT, and CAM files.- DSTV file importing is a standard feature for all Lantek packages.

- Importing SAT and CAM files is available as an optional feature.

- The software allows users to import various file formats, including machining operations, and modify them for production. Once imported, the files are converted into Lantek Flex3D’s native format, enabling easy and intuitive modifications. Users can also modify, add, or delete any machining operations required for the profile.

Lantek Flex3D SteelWork can interpret the various properties of each file, such as material thickness, material type, and quantity, as long as these attributes are supported by the imported format.