Description

- 7.08 inch opening height capacity on the upper beam.

- Eccentric upper beam power transmission system for rapid clamping/unclamping.

- 0.39 and0.98 inch wide single piece folding tools as 2 sets.

- ERFOLD BASIC CNC LBL Cnc control software on 15.6″ touchscreen controller with swivel arm.

- 29.5 inch servo backgauge system with feather grooves.

- 0-150° folding angle.

- Manual folding beam adjustment.

- Front light barriers.

- Solid lower beam tool without channels

STANDARD SPECS AND ACCESSORIES:

- UPPER BEAM

- Clamping beam with 4.72 inch opening height without tools and 45° beam geometry

- Thanks to fast eccentric system, clamping speed is increased up to 3.93 inch/sec

- Thanks to its brass and oil-free friction plates on the linear guides, you can work for years without any lubrication or maintenance

- Also thanks to the protective bellows, no dirt or dust is allowed in the swivel parts of this axis

- 29.5 INCH SERVO BACK GAUGE WITH RECTANGULAR SHEET SUPPORT TABLE

- 29.5 inch servo driven back gauge system with feather grooves only

- 29.5 inch long rectangular sheet support table with stainless ball-casters

- Sliders can be pulled back to create space for down flanges at the back of the bottom tool

- SOLID LOWER BEAM (WITHOUT CHANNELS) AND FEATHER GROOVES

- To avoid unwanted scratches and cracks on the painted sheets caused by lower beam channels, we can build the lower beam without channel and also with special design gauging arms produced by flexible feather steel (0,5 mm thick) so that the arms can approach until the end of the lower beam to the edge and can be clamped between the upper beam tool and lower beam tool together with the sheet.

- FOOT PEDAL WITH 3 SWITCHES

- 3 switch foot pedal with panic button function on two steps.

(Sudden step on left pedal = clamping beam goes up immediately)

(Sudden step on middle pedal = folding beam and all axis stops immediately) - VERTICAL OR HORIZONTAL FRONT LIGHT BARRIERS

- For operator safety, front light barriers are located at the left and right front side of the machine, managed by safety plc and prevent unwanted interventions to avoid accidents. You can choose as horizontal or vertical or you can completely remove the light barriers from your configuration.

- TOOL HOLDERS

- 2 stacks of tool holders that can carry 2 single piece folding tool or clamping beam sharpnose tool

- ERFOLD BASIC NUMERIC CONTROLLER SOFTWARE

- Very user friendly, iconic screen layout

- 15.6″ tft panel touchscreen controller on swivel arm

- Windows based Erfold software that allows you to store and reload back ups of the factory settings or saves programmes easily

- 128 gb memory for unlimited receipt storage

- Line by line part programming by entering numerical values of the axes for each step

- Creating, saving, loading parts with different names, materials and sheet thicknesses

- Open or drop hemming function

- Multi radius bending function as by pressing or by bending

- Backgauge finger pause and on/off functions

- Material database control for springback correction and folding beam height correction regarding material type, thickness and length

- Piece counter for lot production

- Manual axis controls, alarm and error indications, machine detailed parameter pages

- Remote service connection via wireless internet

- User authorization with special passwords.

- Can be upgraded to 2D graphical software after installation

- STANDARD TOOLS

- UPPER BEAM PIECE SHARP NOSE TOOL

- Grinded material, single piece, 20° nose angle

- BEAM GEOMETRY

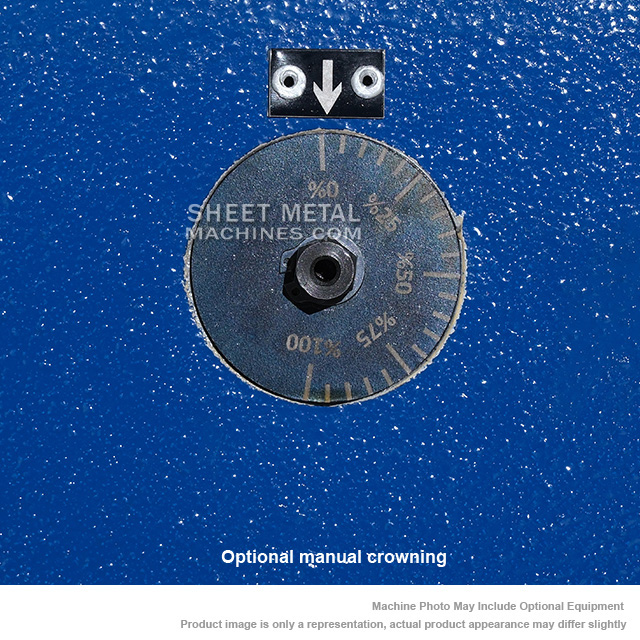

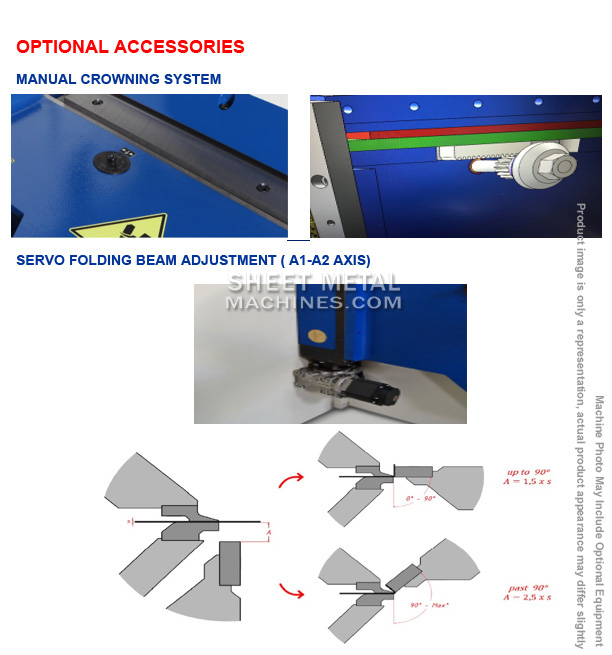

- MANUAL FOLDING BEAM ADJUSTMENT

- Manual height adjustment of folding beam according to the sheet thickness or bending point radius

- Located in left and right side and should be adjusted equally on both sides as thickness x 1 for sharp bending radius or thickness x 1,5 /2,5 for more oval radius.

- More you lower the folding beam, more you have to increase the bending angle in the programme to be able to catch the right bending angle.

SPECIFICATIONS:

|

Max sheet length

|

81 in. (6.75 ft)

|

|

Mild sheet

|

0.098 in.

|

|

Stainless

|

0.059 in.

|

|

Aluminum

|

0.137 in.

|

|

Dimensions

|

132 x 83 x 73 in.

|

|

Weight:

|

5,622 lbs.

|

TECHNICAL PARAMETERS OF 11 AXIS

|

Upper Beam

(Z axis) |

Opening height

(without tools) |

4.72 in.

|

|

Motor Power

(Sew Eurodrive AC) |

1,1 kW

|

|

|

Transmission system

|

Eccentric

|

|

|

Clamping speed

|

3.54 in./sec

|

|

|

Folding Beam

(Y axis) |

Folding angle

|

0 – 150°

|

|

Motor Power

(Sew Eurodrive AC) |

2,2 kW

|

|

|

Folding Speed

|

90°/sec

|

|

|

Folding Beam Height Adjustment

(A1-A2 axis) |

Adjustment height

|

0 / -1.37 in.

|

|

Control

|

Manual

|

|

|

Back gauge system

(X axis) |

Movement speed

|

11.8 in./sec

|

|

Motor Power (Servo)

|

400 W

|

|

|

Positioning / repeatability accuracy

|

+/- 0,1 mm

|

Specifications are subject to change without notice.

NOTE: Data is provided by the manufacturer.

WARRANTY: 1 YEAR – Parts

OPTIONAL ITEMS – CALL FOR PRICE:

- 39.37 or 59 inch servo backgauge system with rectangular sheet support table.

- 2.36 or 3.54 inch high segmented goat foot tool set.

- Manual crowning system.

- Servo folding beam adjustment.

- ERFOLD ADVANCED 2D/3D Cnc Graphic Control Software.

- Omega geometry upgrade on lower and folding beam.

- Manual conical backgauge finger.

- Motorized conical backgauge system.

- Pneumatic goat foot tool quick clamping system

- ERFOLD ADVANCED 2D CNC GRAPHICAL CONTROL SOFTWARE

- Windows based software specifically designed for folders and %100 owned by Erbend

- 15.6″ capacitve LED touchscreen controller on swivel arm

- LBL Editor: You can adjust the bending steps line by line by entering the numeric values of axis targets or measures.

- 2D part editor: you can create a new bending programme by drawing in graphic mode and visualize in 2D graphical screen

- You can determine and change the bending sequence on the created part while you are making graphical collision control

- Capability of choosing material type, thickness, springback, bending correction and creating data base for every type of material type, thickness and length

- Authorization with password

- 128 GB hard disk space which allows you to save unlimited data

- Detailed alarm,tooling and parameters page

- LOWER AND FOLDING BEAM WITH OMEGA GEOMETRY

- Thanks to the special design and more clearence with omega beam geometry of lower beam and folding beam, the parts with downwards flanges, like omega profiles, trapezoidal profiles can be executed more easily.

- 2.36 or 3.54 INCH HIGH SEGMENTED GOAT FOOT TOOL SET

- MANUAL CROWNING SYSTEM

- On long and thin sheets, in order to prevent the banana shape bends, you just need to adjust the crowning between %25 and %100 to give more support from the middle side of the folding beam

- SERVO FOLDING BEAM ADJUSTMENT ( A1-A2 AXIS)

- Servo driven and cnc controlled folding beam height. Your bending height is calculated automatically according to the parameters and set just before the bend.

- LONGER SHEET SUPPORT TABLE

- 39.37 or 59 inch rectangular sheet support table and back gauges

- Front side gauging arms + middle and back side triangle fingers

- Movable sliders for down flanges + steady side gauge

- MOTORIZED CONICAL BACKGAUGE SYSTEM

- Dual axis cnc servo motorized control of the backgauge as X1 and X2 axis

- X1 remains fixed, X2 moves forward to create max 5° conical angle

- Laser beam indicator for the reference line of the sheet edge on the lower beam (manually placed on the sliding rail regarding the software’s indication of edge position)

- SUCTION CUPS ON THE TABLE SUCTION CUPS ON THE TABLE

- Thanks to the suction cups placed on the front gauging group;

- Misalignment of the sheet is avoided.

- Dropping down of the sheet because of downwards flanges is avoided.

- No need to support the sheet anymore from the front side during multi radius bends.

- If the gauging side of the sheet is oval or can not be gauged well to the standard fingers/gauges, you do not need to adjust it again in each bending step.