Description

Built from name-brand parts and steel plate, this industrial press brake will stay rigid and accurate. You can program the bend depth and back gauge for efficient production.

- Delivers 50 tons of pressure over its entire 78” length.

- Long enough to bend 6-foot pieces of mild steel.

- Runs on 220-volt 3-phase power.

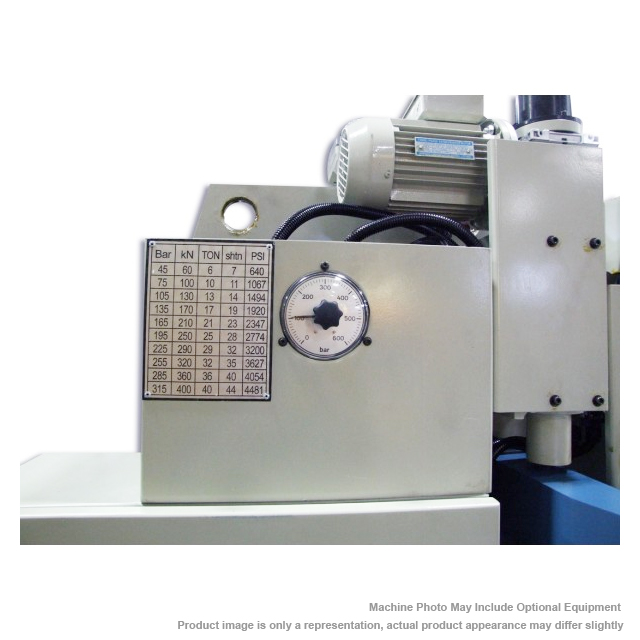

- Industrial-grade hydraulic system with a Vickers/Eaton pump will last for many years at peak capacity.

- NOKhydraulic seals from Japan are some of the best in the industry. They’ll help the hydraulics run smoothly.

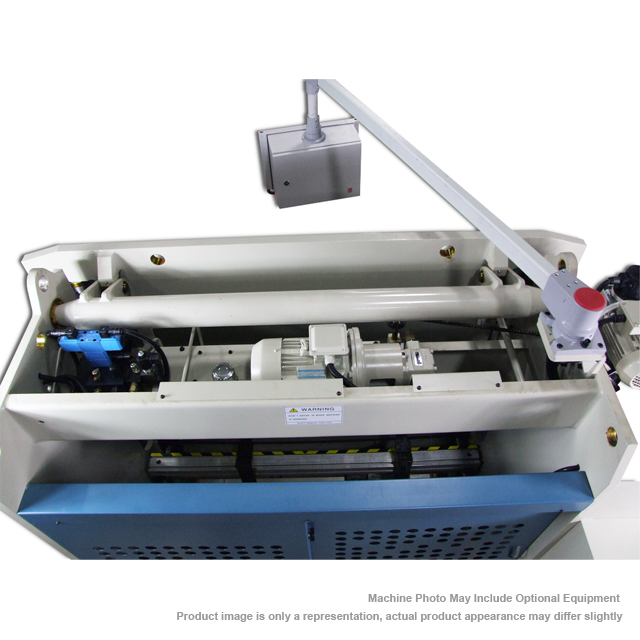

- Torque tube connects the 2 hydraulic cylinders, so they stay synchronized and parallel to the bending table at all times.

- Chain drive linkage keeps hydraulic cylinders in time with each other, so the machine remains balanced and lasts longer.

- Hydraulic cylinders are located in the back of the machine for convenient fluid changes.

Accurate, User-Friendly Control System

- Runs in single-bend mode or programmable mode.

- Comes standard with 2 axes of control: stroke and back gauge distance.

- Simple controller is so intuitive that you could train someone to use it in 5 minutes.

- Programmer stores up to 40 programs with up to 25 bends per program, great for saving time on production.

- Bending is accurate to +/- .01mm, ensuring that parts come out right the first time.

- Main electrical components made in Germany by Weidmueller and Schneider will give you years of trouble-free productivity.

- Foot pedal brings the stroke up and down. Just input your specs on the controller, then press the pedal for each bend.

- You can make a complete part without touching the controller. Push the metal in while pressing the foot pedal.

- Choose between 2 speeds: a rapid approach and retract and a slow bending speed.

- Faster speed option lets you reduce cycle times and bend more quickly.

- Chain drive back gauge system uses tried-and-true technology that you can easily maintain.

- The 23″ back gauge can advance or retract according to programmed instructions.

Rigid Steel Construction and Included Tooling

- Fully-welded all-steel framework helps prevent deformation and minimize flex during the bending process.

- Weighs a robust 6,000 lbs. for massive structural strength that ensures accurate results.

- Includes support arms around 2 feet in length.

- Comes standard with tooling: a multi-Vee bottom die and gooseneck punches (European Style).

- Quick-release tool holders let you make changes easily. You only have to open a lever and it drops the top die out. No time-consuming cap screws!

- Crowning adjustment dial gives you the option to deliver more pressure in the center of a bend for consistency all the way across.

- Safety light curtains prevent the machine from bending when someone is too close.

- Light curtains will swing open and get out of the way when you’re doing a tool change.

Fast Shipping and Expert After-Sale Care

- This hydraulic press brake ships fully assembled. Just uncrate it, plug it in, and get started.

- We keep machine handling to a minimum to reduce the risk of damage. The flatbed truck that leaves our facilities is the one that shows up at your door.

- Replacement parts are in stock at our Wisconsin headquarters, so we can get them to you quickly.

- We offer a 1-year parts warranty, as well as lifetime technical support by phone.

SPECIFICATIONS:

Table Length: 78.7″

Back Gauge Length: —

Return Speed: 3.5″ / sec.

Maximum Pressure: 45 tons

Throat Depth: 7.87″

Stroke Distance: 3.93″

Approach Speed: 3.93″ / sec.

Back Gauge Motor: 1/2 hp

Bending Speed: .393″ / sec.

Main Motor: 4 hp

Distance Between Housings: 64.5″

Distance From Table To Ram: 11.81″

Power: 220V / 3-phase

Shipping Dimensions: 117″ x 61″ x 85″

Shipping Weight: 6,600 lbs.

Specifications are subject to change without notice.

NOTE: Data is provided by the manufacturer.

WARRANTY: 1 YEAR – Parts