Description

- Column type construction.

- Cylinder with auxiliary square post design.

- Saw frame lift stability, outstanding heavy duty cutting.

- Material selection, cutting rate.

- The saw is constructed buy laser cutting the various component parts to exacting tolerances. They are then welded in place by state-of-the-art robotic welders in out welding cells. Using robots allow for precise, strong and consistent welds. This is just another way JLH Saws provide the upmost in quality and precision.

- Consistent accurate tensioning is provided by a hydraulic cylinder.

- The shuttle vise system travels on a large liner rail on both sides of the bed. The main bed of the saw is a roller type bed. Vises are double retracting with hardened wear plates installed. Overhead clamps are included in the productivity package. Vises “float” over the bed and upright rollers fill out this complete package.

- Accurate & fast positioning are accomplished through a magnetic scale. One advantage to this type a measuring is that the scale can be placed out of the coolant area and completely protected.

- Unlike many bandsaw manufacturers that use a worm and gear type gearbox; JLH Saws uses a highly efficient spiral bevel gear and cylindrical gear combination reducer. The drive motor has a direct connection to the gear box eliminating the need for costly belt replacements. Drive motor is inverter controlled.

- A large coolant tank ensures excellent working conditions for the saw blade and work piece. Electrical coolant pump provides continuously circulation during the cutting process. The saw can also be equipped with a micro-spray coolant system (MQL). The MQL system has fully adjustable coolant time & volume on it for easy control by any operator. The chip conveyor is a hollow core style controlled by a hydraulic motor.

- All JLH Saws use a modern and logical hydraulic system. Using the highest quality world class components for years of reliable operation.

- All electrical cabinets are built to international standards. They are well laid out, wired neatly and labeled for ease of repair.

- JLH Saws Control provides latest in PLC based control technology. JLH Saws Control controls are programmable up to 100 different jobs including quantity and length of cut. The control automatically compensates for kerf loss after data input and requires no manual calculation of number of times to index. The control also automatically shutdowns the machine, blade motor, and hydraulics, once the programmed number of cuts or out of stock situation has been achieved. The system includes an error feedback function enabling rapid troubleshooting through an error code to be displayed in the event of a malfunction.

- JLH Saws Control Features include:

- 10″ Touch screen

- PLC controller

- 100 individual jobs can be programmed and stored

- Stored program(s) may be easily recalled and executed at will.

- Blade Speed Display

- Optional Blade Deviation Detection monitor can be controlled directly from Touch Screen

- Automatic Kerf Loss Compensation & Automatic Multiple Indexing up to 999”

- Error Code Display Provides simplified self-diagnostics.

- The operator’s control station is ergonomically located on the front side of the saw. It is convenient and user friendly. All operator controls are positioned on the control station and clearly labeled for ease of operation.

SPECIFICATIONS:

|

MODEL

|

H-20PRO

|

|

|

Maximum Cutting Capacity

|

Round

|

20 in.(530mm)

|

|

Square

|

20 x 20 in. (530 x 530 mm)

|

|

|

Bundle

|

16.1 x 8.7 in. (410 x 220 mm)

|

|

|

Saw Blade

|

Speed

|

32.8-262.5 SFPM (10~80 m/min)

|

|

Size

|

244.1 x 2.0 x 0.05 in.

(6200 x 41 x 1.3mm) |

|

|

Tension

|

Hydraulic Controlled

|

|

|

Motor Output

|

Saw Blade

|

10.1 HP (7.5 KW)

|

|

Hydraulic

|

2.0 HP (1.5 KW)

|

|

|

Coolant

|

0.18 HP (135 W)

|

|

|

Oil Tank Capacity

|

Hyd. Oil

|

18.5 Gal (70L)

|

|

Coolant

|

36.9 Gal (120L)

|

|

|

Voltage

|

220V / 3 Phase / 60Hz

|

|

|

Single Feed Stroke

|

19.7 in. (500mm)

|

|

|

Bed Height

|

30.54 in.

|

|

|

Machine Weight

|

7,250 lbs. (2500 kg)

|

|

|

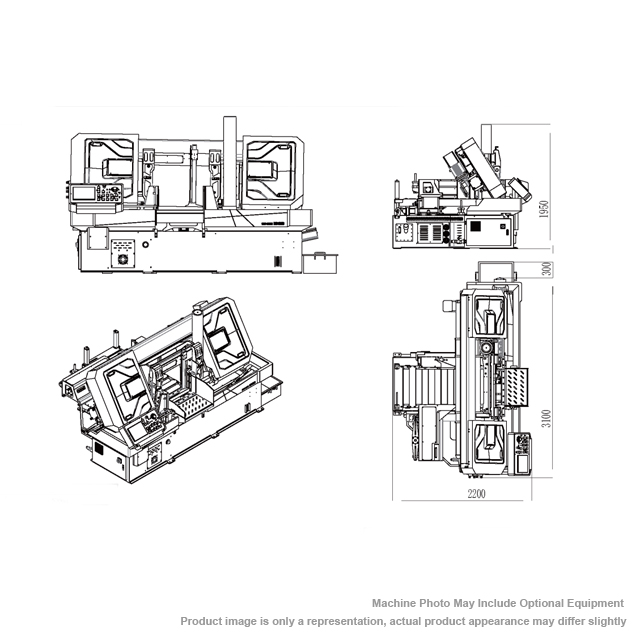

Machine Measurement (LxWxH)

|

89 x 122 x 77 in.

|

|

|

Drive and Idle Wheel Size

|

φ27.1 in. (740mm)

|

|

Specifications are subject to change without notice.

NOTE: Data is provided by the manufacturer.

3 YEAR WARRANTY – Mechanical Parts

2 YEAR WARRANTY – Electrical Parts

1 YEAR WARRANTY – Labor

OPTIONAL ITEMS: CALL FOR PRICE

Variable Vise Pressure Control System

Powered Chip Auger

Hydraulic Top Clamp (removable, short stroke)

6’6” (2M) Idle Roller Table 6.5’ Long, with Vertical Alignment Rollers

9’10” (3M) Idle Roller Table 6.5’ Long, with Vertical Alignment Rollers

Powered Roller Tables

Transformer for 480V, 3 Phase