Description

- Made in Taiwan

- Acra’s LCTM-1 CNC 3 Axis Vertical Milling Machine with Acu-Rite MillPower Controller features the following:

- From the moment you power up your MILLPWRG2 system, you’ll know it was built with convenience in mind. From the exceptional clarity of a large full-color LCD display to the added advantage of full 3D contouring capabilities and menu-prompted conversational programming, essential functions are only a key stroke away. Use MILLPWRG2 as a full function digital readout system, a programmable NC control or both. It’s powerful enough to handle any job and easy enough for anyone to operate. No prior programming experience necessary.

- Powerful Easy: Faster set-ups, shorter run times and a major boost in productivity are just one “powerful easy” retrofit away. The new ACU-RITE MILLPWRG2 control and retrofit kits can turn just about any knee mill into a productive CNC machine.

- User-Friendly: Standardized menus make it easy to program common features, simply press any function key and follow the prompts. Use MILLPWRG2 for arcs, blends and circles in any size, shape or pattern your print requires. There is no need to set up rotary tables or other devices. MILLPWRG2 also includes an engrave option for engraving alphanumeric characters vertically, horizontally, diagonally or along an arc.

- Shop Tough: Every MILLPWRG2 system includes components that have been designed, manufactured and tested to withstand the elements of contamination found in even the harshest machine shop environment.

- Versatile: Use MILLPWRG2 as a full function DRO, an intelligent power feed or a programmable CNC. This versatile system allows the operator to switch from fully automatic mode to manual mode in just seconds. Import and run G-Code files from CAD/CAM programs to machine full 3D contoured parts. With optional spindle control, you can automatically control your spindle’s speed and/or direction on milling machines that are equipped with an electronic variable speed spindle.

- 3-D Graphics System: Intuitive navigation menus eliminate the need for multiple screens, while improving efficiency and accuracy. Program cycles using a simple, easy-to-understand set of machinist language prompts, are accompanied by content-specific “help” graphics.

- 2-Year Warranty for CNC Controller.

- SPINDLE UNIT:

• R8, NST30, NST40 are available.

• Made from one piece of Ni-Cr alloy steel.

• Supported by two precision angular contact and one ball bearing to ensure rigidity.

• Inner taper is hardened and precision grounded. - MILLING HEAD GEAR AND QUILL:

• Harden and grounded spindle, quiet and smooth, free of noise and vibration.

• Uses dynamically balanced pulleys and precision bearings.

• 3HP Spindle Motor.

• Spindles back gear runs in grease packed housing to ensure less fatigue, strength and low noise.

• Chrome coated and mirror grounded finished quill. - RIGID HEAD TILTING SYSTEM:

• The Heaf knuckle is our design patent. This structure greatly increase the stability and rigidity, when the vertical head is titled at any angle, front and back to perform complicated work. There are 6 T-bolts to lock the knuckle to the Ram instead of 3 bolts. - ADJUSTABLE BACKLASH NUT:

• Unique double nuts and backlash adjusting design, contact face enlarged ensuring accuracy over term and easy for backlash adjustment. - Acu-Rite MillPower 3 Axis Controller Specifications:

Processor: 1.4 GHz Celeron M

CNC User Memory: 1.25 MB

Display: 12.1” 1024 x 768 Color LCD with LED backlight

Internal Storage: 2.5 GB Flash (User)

Remote Pendant (Stop / Go): Yes

Housing: Die Cast Metal (Bezel & Back Sheet Metal)

Connections: Ethernet, USB (x2), RS-232

Protection: IP 54 (front) / IP 40 (Back)

Feed Override: Potentiometer

Error Compensation: Linear & Bidirectional Non-linear

Graphic View: 2D Line / 3D Line / 3D Solid

Program Size Limit: 9999 Steps - Standard Features for Controller & Mill:

• USB + Ethernet Compatible.

• Simplified Navigation that Eliminates Multiple Menu Screens.

• Upgrades Available for all Legacy MILLPWR Models.

• 12.1″ High Resolution Display with 3D Graphics.

• 1.4 GHz Processor.

• Available Off-Line Software.

• Estimated Run time Feature.

• Expanded Tool / Datum Offsets.

• Machine Specific Bracketry.

• G2 CNC Control.

• Remote Stop/Go Switch.

• Ball Screws.

• Precision Linear Encoders (1µm/0.00005” Resolution).

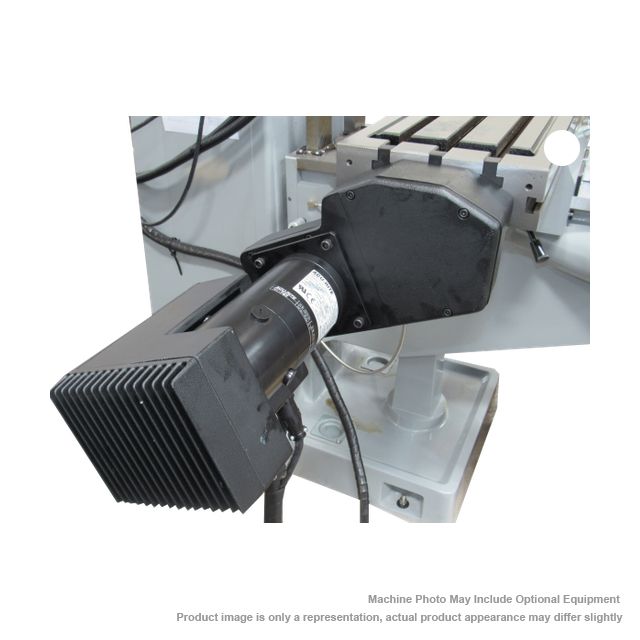

• Servo Drives and Motors.

• Motor Mounting Castings and Hardware.

• Handwheels.

• Console and Encoder Mounting Hardware.

• Milled Oil Grooves

• Hard Chrome Ways

• Hand Scraped Saddle

• Meechanite Casting

• ABEC-7 Spindle Bearings - ALL ACCESSORIES AND CONTROL, INSTALLED

- MILLPOWER WARRANTY, 2 YEARS, FROM SHIP DATE FROM MILLPOWER

- CONFIRM DELIVERY AT TIME OF ORDER

- ACRA MACHINERY IS NOT RESPONSIBLE FOR TRAINING

STANDARD EQUIPMENT:

- 1 MICRON (UM) GLASS SCALE FEEDBACK, ALL AXIS

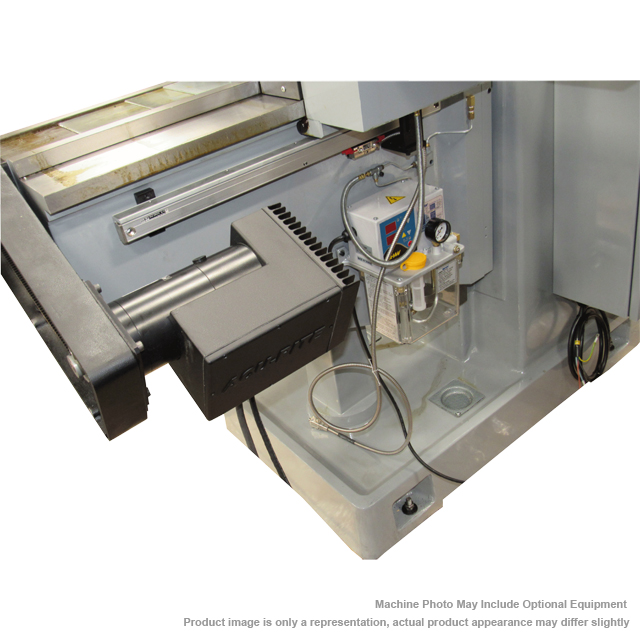

- AUTO LUBE, NEW PRECISION GROUND BALL SCREWS

- Harden & Ground Ways

- Harden & Ground Table

- Quill Heat Treat Hardened & Chromed

- Acurite MillPwr CNC Control

- Auto Lubrication

SPECIFICATIONS:

MODEL: LCTM-1 3X

Table Size: 10″ x 54″

Max Table Load: 990 lbs.

X Axis Travel: 33″

Y Axis Travel: 16″

Z Axis Travel (quill): 5″

T-Slots: 3 x 0.625″ x 2.5″

Ram Travel: 18.5″

Knee Travel: 15.3″

Throat Distance: 9.6″ ~ 28.1″

Spindle to Table Top: 5.31″ ~ 20.7″

Spindle RPM: 60-4500

Quill Feeds: 0.0016″/0.0031″/0.0063″

Spindle Nose: R-8 or #30 NST

Main Motor: 3 HP

Voltage: 230/460V AC ~ 3 PH

Dimensions: 82″ x 80″ x 90″

Weight: 3,500 lbs.

Specifications are subject to change without notice.

NOTE: Data is provided by the manufacturer.

WARRANTY: 1 YEAR – Parts

OPTIONAL ITEMS:

- AC Inverter Drive 230V: $1,500

- W-Axis Scale on Knee: $1,250

- AMI Deluxe Option … (FAGOR 8055i no charge): $3,300

- Single Phase Spindle (Not AC): $300

- AC Inverter Drive 460V: $250